In aerospace maintenance, safety depends on detecting even the smallest cracks. For inspections to be reliable, surfaces must be cleaned without masking or altering potential defects.

This is where wet blasting proves its value. It delivers a clean, inspection-ready surface that supports accurate Non-Destructive Testing (NDT):

• Flushes out oils, corrosion and debris from cracks with precision

• Does not peen over or smear cracks shut, keeping them open for detection

• Prevents abrasive particles from embedding into the surface, which could interfere with NDT

• Leaves a smooth, consistent finish without introducing stress points

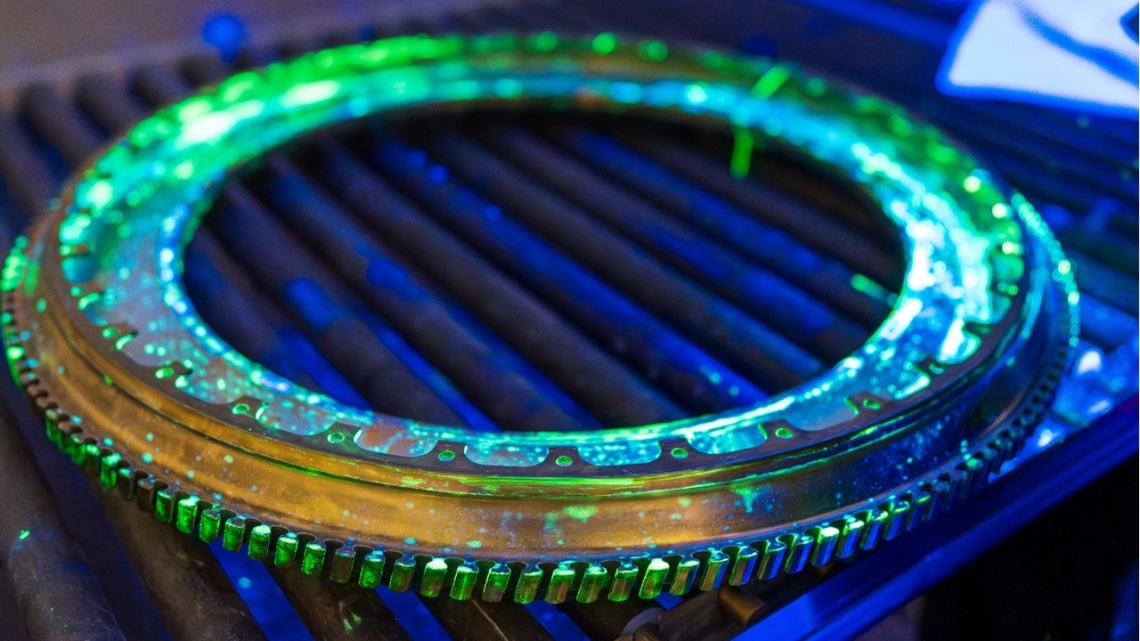

• Enhances the reliability of fluorescent penetrant inspection (FPI) and other NDT methods by keeping cracks fully visible

By ensuring cracks remain open, clean and detectable, wet blasting strengthens the effectiveness of NDT and supports compliance with FAA, EASA and OEM airworthiness standards.

Learn more about the applications and advantages of wet blasting for MRO