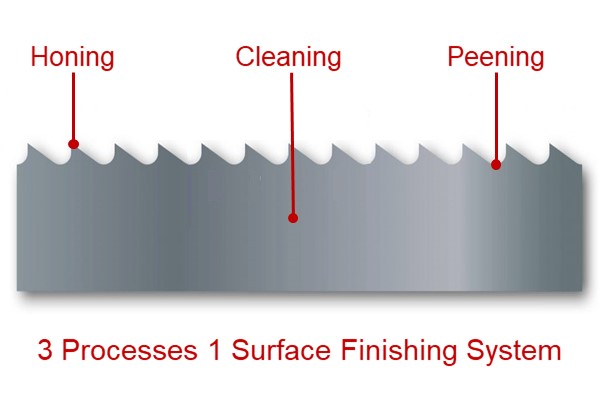

As well as peening the gullet of bandsaw blades to prevent failure, wet blasting also cleans the blades and hones cutting teeth

Peening is an important surface treatment process with various benefits and applications in different industries like tooling and aerospace. We explain the benefits of peening by wet blasting below, but to start with, here are some reasons why peening is so important:

Improved fatigue resistance: Peening produces compressive stress on the surface of a material, which helps to counteract the tensile stresses that can lead to fatigue and failure. By introducing compressive stresses through peening, the material's fatigue life can be significantly enhanced, resulting in improved durability and reliability of components.

Stress relaxation: Peening can help to relieve residual stresses in materials. When materials undergo processes like welding, machining, or heat treatment, residual stresses can be introduced, which may have negative effects on the material's structural integrity. Peening can relieve and redistribute these stresses, thereby improving the overall stability and reducing the risk of stress-related failures.

Improved resistance to corrosion and stress corrosion cracking: Peening can enhance the material's resistance to corrosion and stress corrosion cracking. By introducing compressive stresses on the surface, peening helps to close cracks, reduce the availability of crack initiation sites, and slows down the propagation of cracks. This effectively improves the material's resistance to the corrosive environment and prevents crack growth.

Dimensional stability: Peening can help to improve the dimensional stability of components. By introducing compressive stresses, peening can counteract the tendency of materials to deform or warp under certain conditions, such as thermal cycling or mechanical loading. This is particularly important in industries where precise dimensional control is critical for proper functioning and performance.

Overall, peening plays a vital role in enhancing the mechanical properties, fatigue resistance, and overall performance of materials and components. It is widely employed in manufacturing to ensure the reliability, durability, and safety of various products and structures.

Additive manufactured parts, aerospace turbine and bandsaw blades benefit from peening by wet blasting to help prevent failure

The benefits of peening by wet blasting – The effect of water and abrasive media blasted at a material's surface by air pressure can create a peening effect by converting tensile stresses to compressive stress and in the process improving its mechanical properties. When wet blasting is used specifically for peening, it offers numerous benefits:

Controlled and gentle peening: Wet blasting allows for precise control over the intensity and impact of peening - more control than any other type of finishing process. The addition of water to the process softens the impact of the abrasive media on the surface, resulting in a gentler peening action. This controlled peening helps to avoid excessive deformation or damage to the material being treated.

Enhanced surface cleanliness: The combination of water and abrasive media in wet blasting effectively removes contaminants, such as rust, scale, dirt, and oil, from the material's surface. This thorough cleaning ensures that the peening action is applied directly to the surface, improving the overall effectiveness of the process.

Elimination of dust and airborne particles: Wet blasting suppresses dust and airborne particles, making it a safer and more environmentally friendly alternative to dry blasting methods. The water acts as a binder for the abrasive media, minimising the release of particles into the air and reducing the risk of explosions or respiratory hazards for operators.

Improved surface finish: Wet blasting can provide a smoother and more refined surface finish compared to dry peening methods. The water acts as a lubricant, which helps to reduce the generation of roughness and inconsistently finished surfaces. Wet blasting leaves the entire treated surface with a uniform texture.

Increased fatigue life and component durability: Peening by wet blasting induces compressive stress on the material's surface. This compressive stress helps to counteract tensile stresses that can lead to cracking, fatigue, and failure. It improves strength by giving the material’s grain structure a shallower depth with a more random textured pattern. By enhancing the material's resistance to fatigue and increasing its durability, wet blasting peening can extend the lifetime of components and improve their overall performance.

Versatility and adaptability: Wet blasting peening can be applied to a wide range of materials, including metals, composites, ceramics, and plastics. It is suitable for various industries, such as aerospace, automotive, additive, and other types of manufacturing. Additionally, the process can be adjusted to accommodate different peening requirements, allowing for customisation based on specific material properties and desired outcomes, as mentioned above wet blasting offers more process control than other types of peening processes.

It's important to note that wet blasting peening may have its limitations depending on the specific application and material being treated. Consulting with surface treatment experts and professionals is recommended to ensure the appropriate technique and parameters are employed for optimal results.

Numerous collaborative projects with our customers have helped us perfect peening by wet blasting. Of particular note is the application of several wet blasting machines for peening fan and turbine blades for the aviation industry.

Our wet blasting systems offer excellent controllability, delivering a high-quality consistent result every time. Leading aerospace manufacturers rely on our wet blasting systems for precisely these reasons.