For any company to successfully achieve ultimate utilisation, efficiency and return on investment on a new or existing machine, they’ll need:

Vapormatt 4.0 can help any company realise this, through a partnership approach.

So, what exactly is Vapormatt 4.0, or to give it its full description, ‘Industry 4.0’ and the ‘Industrial Internet of Things’ (IIoT)?

Connecting the physical with the digital

Industry 4.0 takes the digital advances of recent decades, and combines them with physical ‘things’– machines for example – to create highly intelligent, efficient and interconnected systems and processes. An Industrial Internet of Things.

This revolutionary focus on interconnectivity, automation, machine learning, machine-to-machine communication (M2M) and real-time insights and analytics is creating manufacturing and industrial plants of the future – smart factories.

For example, AI can be used to detect corrosion inside a refinery pipe. Real-time production data can uncover additional capacity in a factory. Augmented reality (AR) can help workers operate construction machinery. And low-cost smart sensors can monitor maintenance needs, anticipating repair demands on production lines.

A network of digitally connected industrial devices that monitors, collects and delivers valuable new insights

But Industry 4.0 and IIoT aren’t just about improving manufacturing efficiency. They’re about revolutionising the way your entire business operates and grows.

They’re about people too. Utilising the benefits of digital and real-world machines can better help your staff be more productive by automating tedious or lengthy tasks; freeing up their time for more important activities.

IIoT is an interlinked and holistic approach to manufacturing and the industrial sector. It brings together digital learning, real-world physical ‘things’, and people to deliver unprecedented levels of efficiency, all while reducing costs.

Industries that have adopted IIoT are experiencing transformative operational and financial benefits.

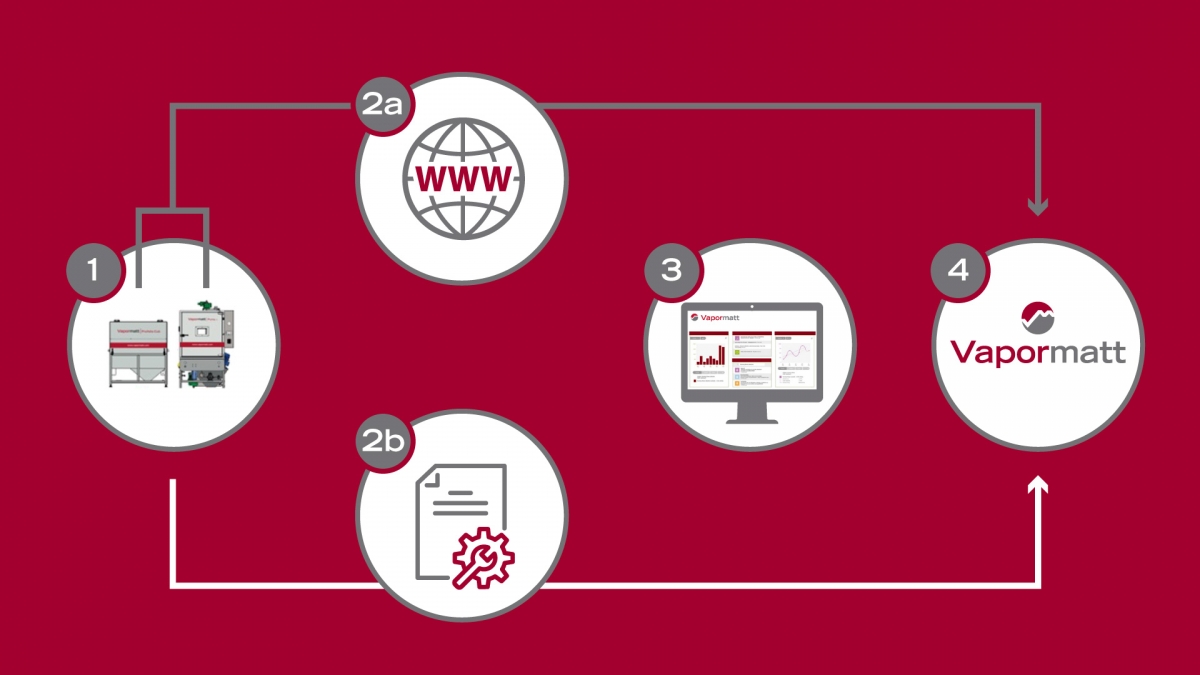

Vapormatt 4.0 is our IIoT solution. Here’s how it works.

Vapormatt wet-blasting machines fitted with Vapormatt 4.0 in your manufacturing facility

JIT spare parts, updates and product information

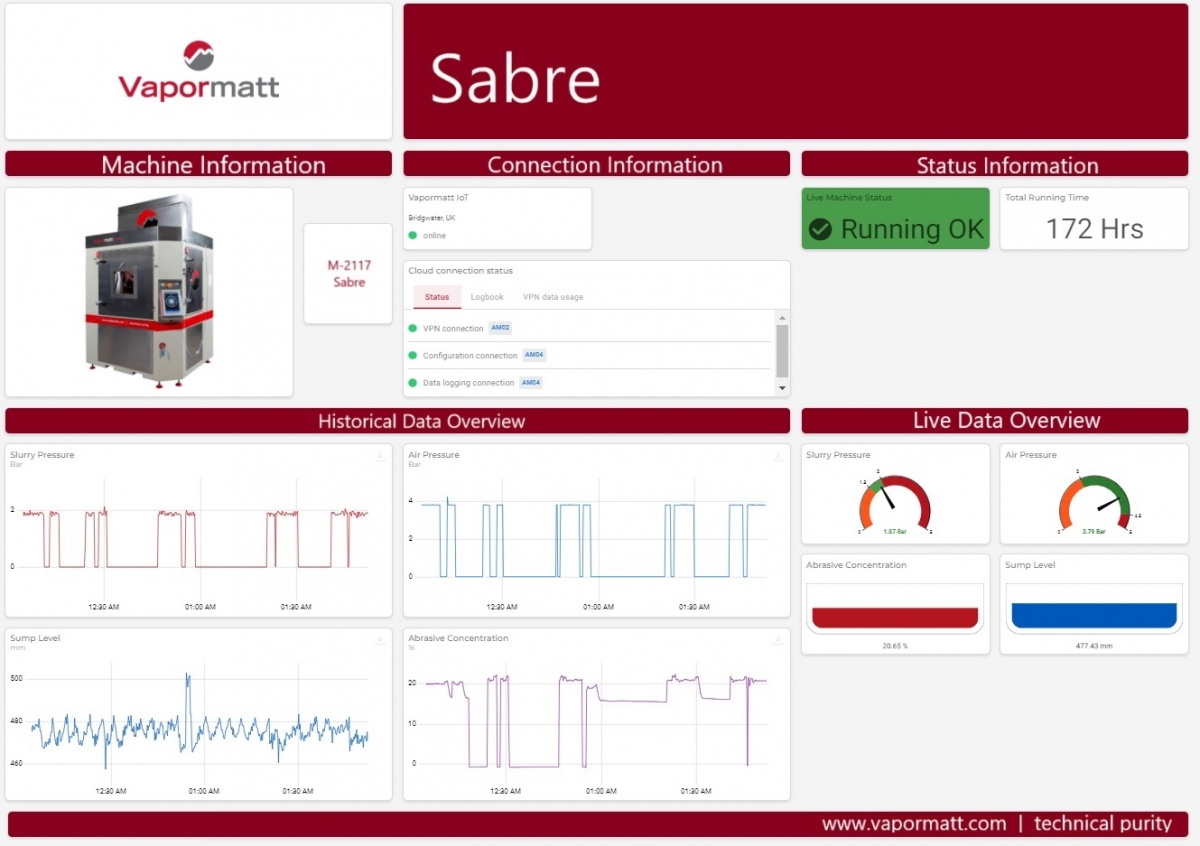

Log in to access user manuals and a bespoke dashboard that can include machine status, maintenance and spare parts order history

The dashboard can be viewed from anywhere and on any platform, provided there is an internet connection

Different levels of automated ordering of spare parts available on a just-in-time (JIT) basis, for maximum production uptime

Our ability to analyse the performance of your system enables us to improve our support

We can alert you to updates on any new technologies or products relevant to your wet-blasting systems

Vapormatt 4.0 is being installed in all our new wet-blasting machines but can also be retro-fitted to existing machines. And with one small monthly fee, all this could be yours.

The Vapormatt system brings together your assets, and gives you advanced predictive and prescriptive analytics that enable you to influence and control working practices and stock holding.

Increase production time and decrease downtime

Increase product quality

Reduce stock holding of spare parts

Increase machine life

Accurately budget maintenance costs while achieving high and quality production patterns.

In the spirit of partnership, Vapormatt has created 4.0 to support our customers and allow them to accurately budget maintenance costs while achieving high and quality production patterns.

We’re committed to helping our customers create an improved and proactive maintenance ‘philosophy’.