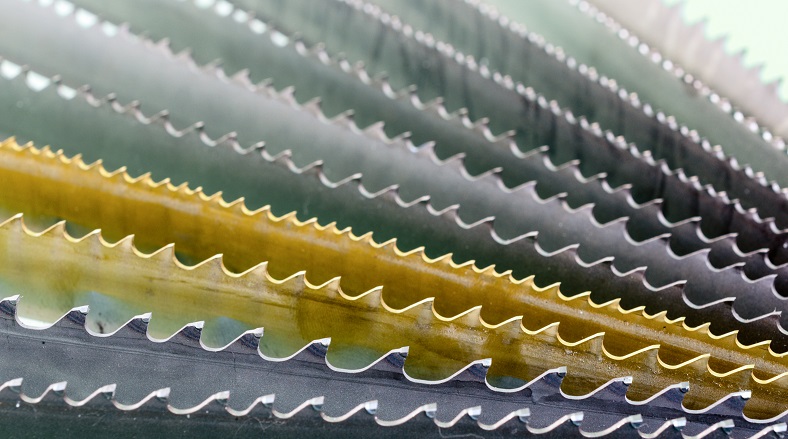

Manufacturers produce high-quality bandsaw blades for improved cutting performance, efficiency, durability, brand reputation, and overall cost-effectiveness in various cutting applications.

CONTACT US TO DISCUSS YOUR BANDSAW BLADE FINISHING REQUIREMENTS

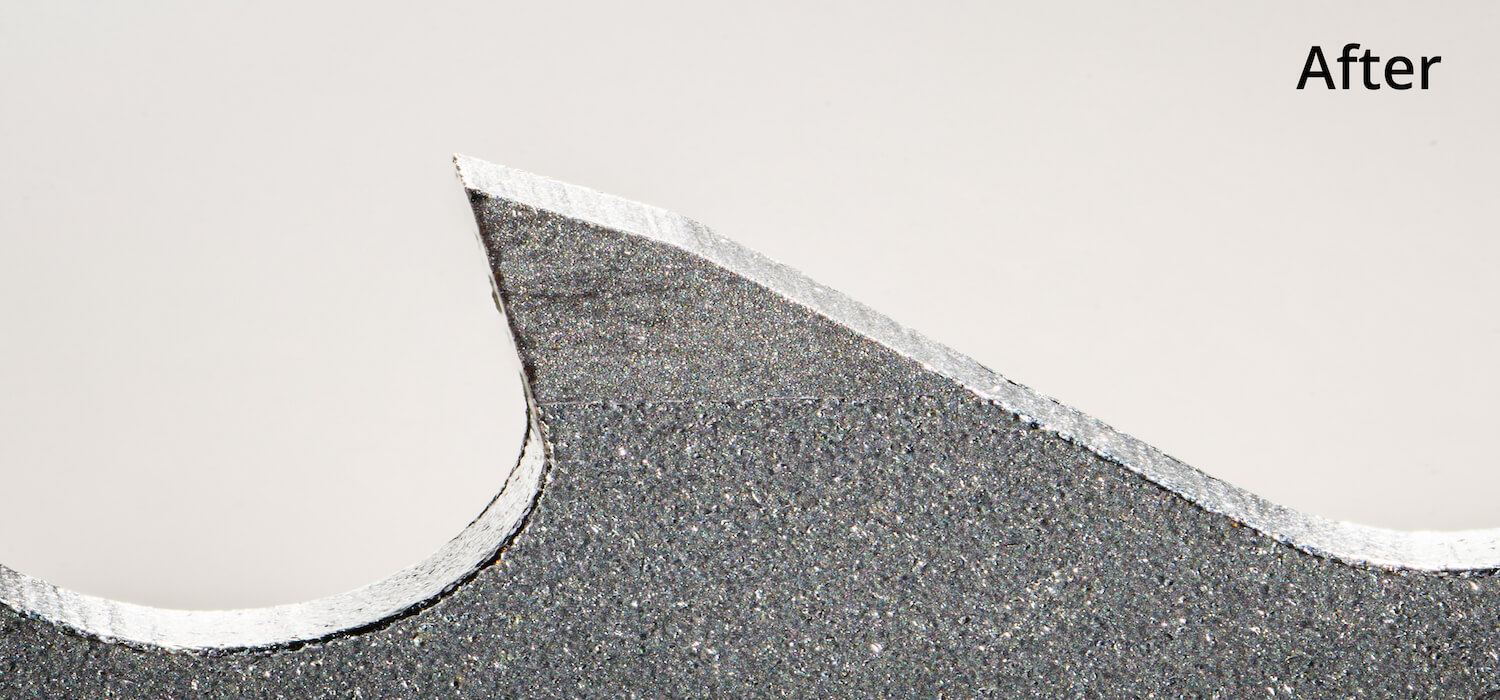

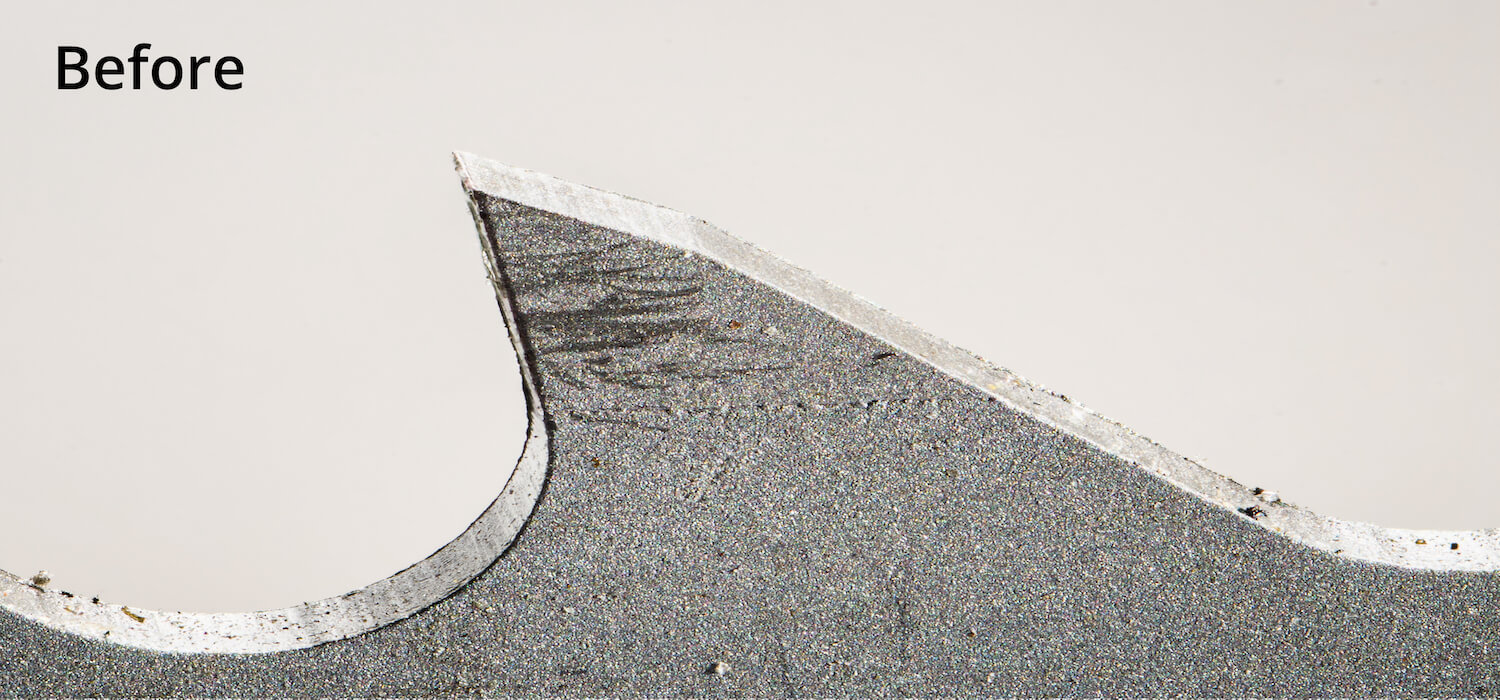

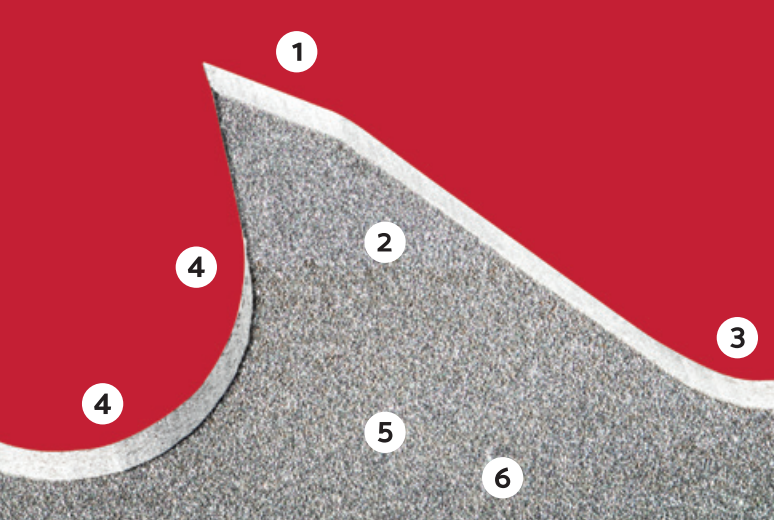

As a manufacturer of bandsaw blades, you will be familiar with the issues that can result in poor-quality blades, overly sharp teeth that chip, cracking in the gullet between saw teeth and a surface that will not readily accept anti-oxidation treatments or branding.

But there is a well-proven technology to resolve these issues:

CONTACT US TO DISCUSS HOW WE CAN HELP IMPROVE THE QUALITY OF YOUR BANDSAW BLADES

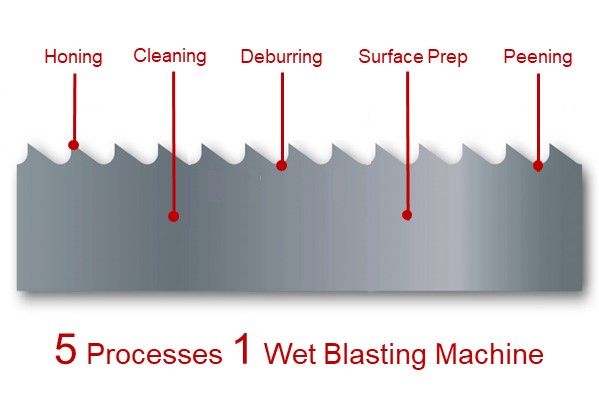

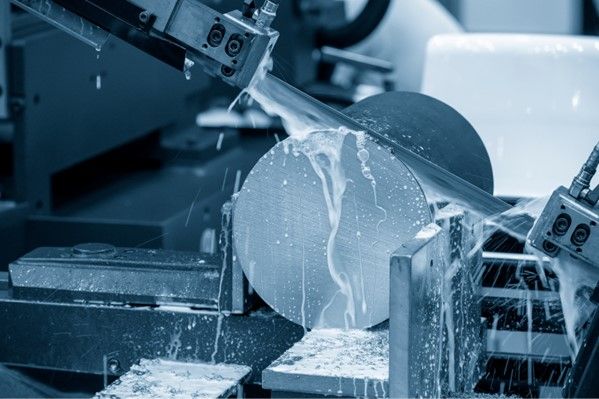

Wet blasting, also known as wet abrasive blasting, aqua blasting, or vapor blasting, is a surface cleaning and finishing process that uses a slurry of water and abrasive media propelled by compressed air to clean, debur, polish, hone, peen or prepare surfaces for coating. Learn more about the wet blasting process by visiting our ‘What is wet blasting?’ page. When it comes to cleaning and finishing bandsaw blades, wet blasting has numerous applications and benefits:

One of our customers recently conducted tests on their reciprocating saw blades to determine how coating preparation was affected by switching from dry blasting to wet blasting.

They found blade life was increased by 3.5 times and cutting speed was increased by 100%.

Our Profelis wet blasting machine, details below, has been designed for the rapid in-line finish of bandsaw blades. Watch our video to learn how the Profelis works and its many benefits.

Wet blasting gives you more efficient, more seamless and more effective production. And for high-precision wet blasting, there’s only one name you need to know: Vapormatt.

CONTACT US TO DISCUSS HOW THE PROFELIS CAN TRANSFORM YOUR BLADE FINISHING OPERATION