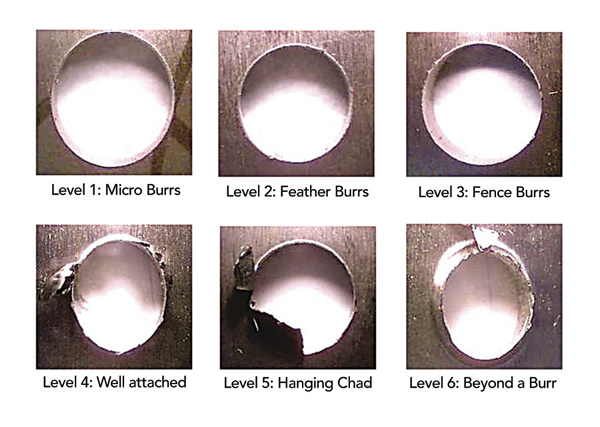

Different burr levels

Deburring is the process of removing burrs, which are unwanted rough edges or protrusions on a metal workpiece. It can be a large challenge in the machining of metals and can limit the production process. We explain the benefits of deburring components by wet blasting below, but first, these are the reasons why deburring is so important:

Safety: Burrs can be sharp and pose a safety hazard to both workers and end-users. Deburring eliminates these sharp edges, reducing the risk of cuts or injuries when handling or using components.

Functionality: Burrs can interfere with the proper functioning of metal components. For example, in assemblies or moving parts, burrs can cause friction, misalignment, or jamming. By removing the burrs, the components can fit together correctly, ensuring smooth operation and optimal performance.

Quality and aesthetics: Deburring improves the overall quality and appearance of components. Burrs can give a rough or unfinished look to the product, which may be undesirable, especially for components that are visible or require a high level of precision. Deburring enhances the visual appeal and can contribute to better surface finishes.

Assembly and joining: Burrs can impede the assembly process, making it difficult to fit or align parts properly. When joining metal components through welding, brazing, or adhesive bonding, burrs can create gaps or prevent a strong and secure connection. Deburring facilitates better assembly and improves the integrity of the joints.

Coating and finishing: If a metal part is intended to be coated, painted, or plated, burrs can interfere with the adhesion of the coating or finish. By removing the burrs, the surface becomes more uniform and suitable for subsequent treatments, ensuring better coating coverage and durability.

Overall, deburring is an essential step in production processes to ensure safety, functionality, quality, and aesthetics of final products, as well as to facilitate assembly, joining, and surface treatments.

Wet blasting is effective at removing metal burrs from holes, wet blasting a metal part, time-consuming removal of burrs by hand

The benefits of deburring by wet blasting - Also known as vapor blasting, wet blasting is a surface finishing process that combines the use of abrasive media and water to remove burrs, sharp edges, and surface contaminants from a variety of materials. Deburring by wet blasting offers several benefits:

Burr removal: Wet blasting effectively removes burrs from machined or fabricated parts. Burrs can hinder the functionality of components and pose safety risks, so removing them is essential. Wet blasting gently erodes the burrs without altering the dimensional accuracy or surface finish of the part.

Burr removal from hard-to-reach places: Wet blasting is particularly effective at removing burrs from difficult to reach places thanks to the flow of abrasive slurry.

Consistent finish: Wet blasting provides a uniform and consistent finish across the entire surface of the part. The combination of abrasive media and water ensures that the material is evenly abraded, resulting in a smooth and refined surface.

Damage avoidance: Being able to alter the abrasive used, which is typically spherical, and the water and air pressure allows users to create very hard or soft deburring conditions that limit the rounding or damage to edges that can occur with alternative methods. Generally speaking, wet blasting is most effective at removing light burrs with a very fine aluminium oxide media and heavy burrs using a stainless steel or ceramic media.

Preservation of surface integrity: Unlike other deburring methods that can generate heat or friction, wet blasting operates at lower pressures and temperatures. This helps preserve the structural integrity of the material being processed, minimising the risk of distortion or damage.

Reduced risk of part contamination: Wet blasting uses water as a lubricant and carrier for the abrasive media. This water acts as a barrier, preventing the generation and spread of dust or contaminants during the deburring process. As a result, wet blasting helps maintain a cleaner and safer working environment.

Enhanced surface preparation: Wet blasting not only removes burrs but also cleans the surface by eliminating rust, scale, oxidation, and other contaminants. This makes it an ideal choice for preparing parts for subsequent processes such as painting, coating, or bonding, as it promotes better adhesion and improves the overall quality of the finished product.

Versatility: Wet blasting can be used on a wide range of materials, including metals, plastics, composites, ceramics, and more. It is suitable for delicate or sensitive components as well, as the process can be adjusted to accommodate different material hardness and surface finishes.

Eco-friendly solution: Wet blasting is a relatively environmentally friendly deburring method compared to traditional alternatives. The use of water reduces airborne dust and the need for chemical solvents, making it a more sustainable and safer option for both workers and the environment.

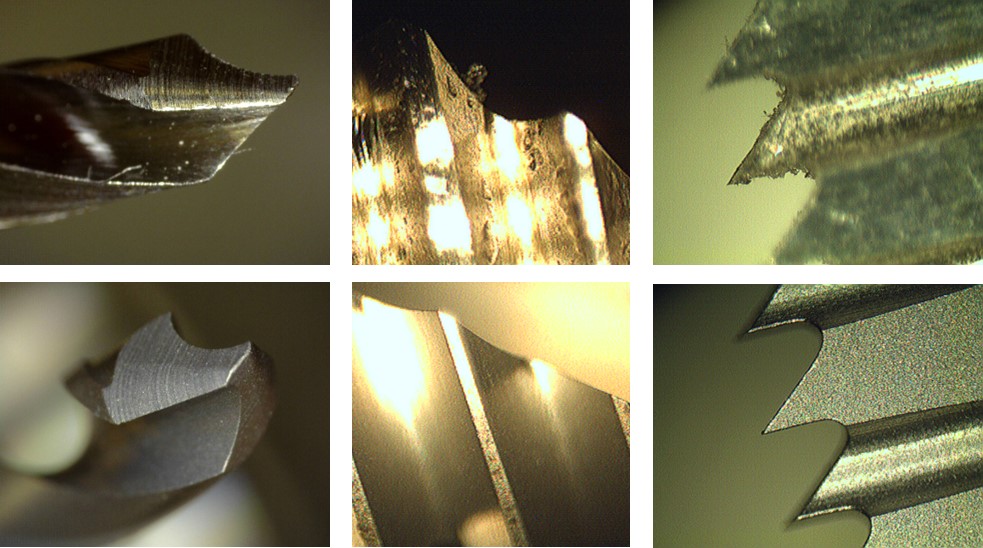

Various tools before and after deburring by wet blasting

Overall, wet blasting provides efficient and effective deburring, while simultaneously offering surface cleaning and surface preparation advantages. Its ability to deliver consistent results and preserve the integrity of the part makes it a popular choice in various industries, including automotive, aerospace, and medical manufacturing.