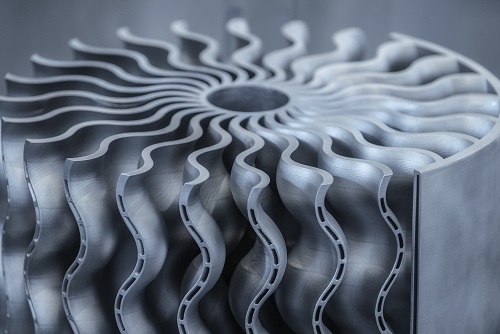

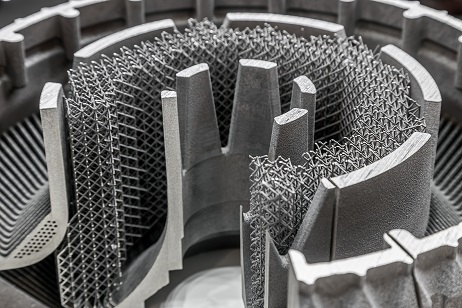

Additive manufacturing (AM) is transforming industries across the globe: from aerospace and defence to automotive and medical. With so many production benefits, it’s no wonder AM’s set to grow by well over 20% per year for the foreseeable future.

Wet blasting (or vapor blasting) is the ideal finishing process for AM thanks to its ability to perfectly finish parts whilst cleaning the complex channels that are often a feature of AM components.

Scroll down for a summary of the many benefits associated with wet blasting AM components if you are already familiar with the benefits of AM. Otherwise, here are some of the benefits of AM that have made it such a success story for manufacturing:

These benefits make additive manufacturing a transformative technology with the potential to revolutionise industries, enable new business models, and unlock innovative design possibilities. However, it is important to consider the specific requirements, limitations, and cost-effectiveness of additive manufacturing for each application or industry context.

Wet blasting offers numerous benefits when applied to AM components. It helps eliminate some of the limitations of AM making it more relevant to more industries more the time. This is how wet blasting can make a difference:

All of these benefits make wet blasting an invaluable process for enhancing the quality, performance, and functionality of additive manufactured components. It is important to note that specific advantages may vary depending on the material, AM process, and desired surface finish. Therefore, it is recommended to consult with experts or conduct testing to determine the optimal wet blasting parameters for a particular application.

Our fully automatic wet blasting machine designed for the rapid finishing of AM components. AM components are loaded into a 350mm diameter x 270mm deep barrel (a larger 500mm diameter x 270mm deep barrel is available for larger loads) and blasted by up to 2 blast guns for the 350mm barrel and up to 4 blast guns for the 500mm diameter. Components are rapidly finished. Rinse and air guns remove any residual media and dry the components.

Our manual wet blasting machine with barrel for multiple AM components and a working area for larger components. AM components are loaded into a 260mm diameter x 260mm deep barrel and blasted by a single-blast gun. A timer is set for the duration of the blast required. Larger components can be blasted outside of the barrel. A 500mm diameter turntable can be specified to make rotation of larger components easier. Rinse and air guns remove any residual media and dry the components.

Our compact manual wet blasting machine with a large working area. The Vapormate has a particularly compact footprint of W735 x H1,664 x D810mm. It is compact enough to fit through a standard doorframe but has a large working area of W680 x H520 x D680 that accommodates all but the very largest of AM components. Like all our wet blasting machines it is fully featured with air pressure control and rinse and air guns to ensure users achieve the perfect finish.

To learn more about these machines, including videos and technical specifications, scroll down to the ‘Related Machines’ section below.