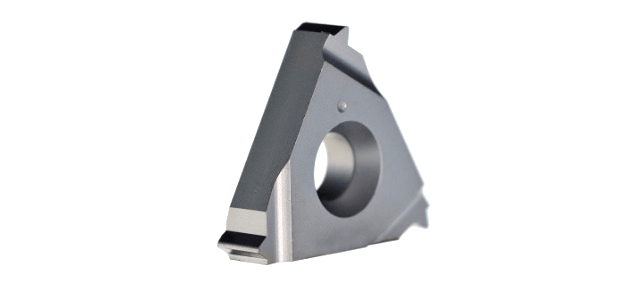

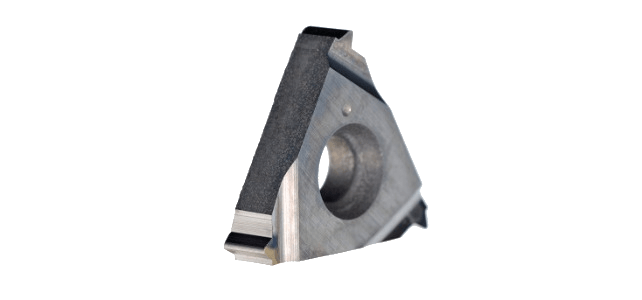

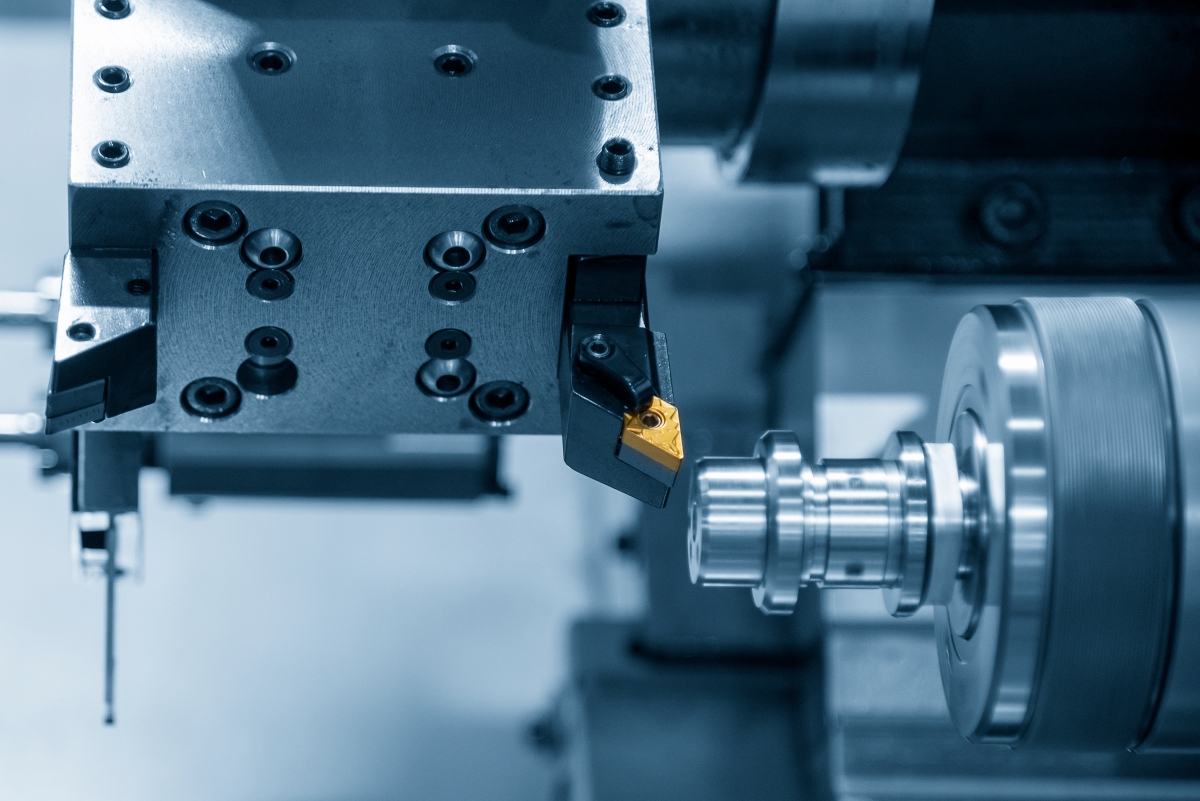

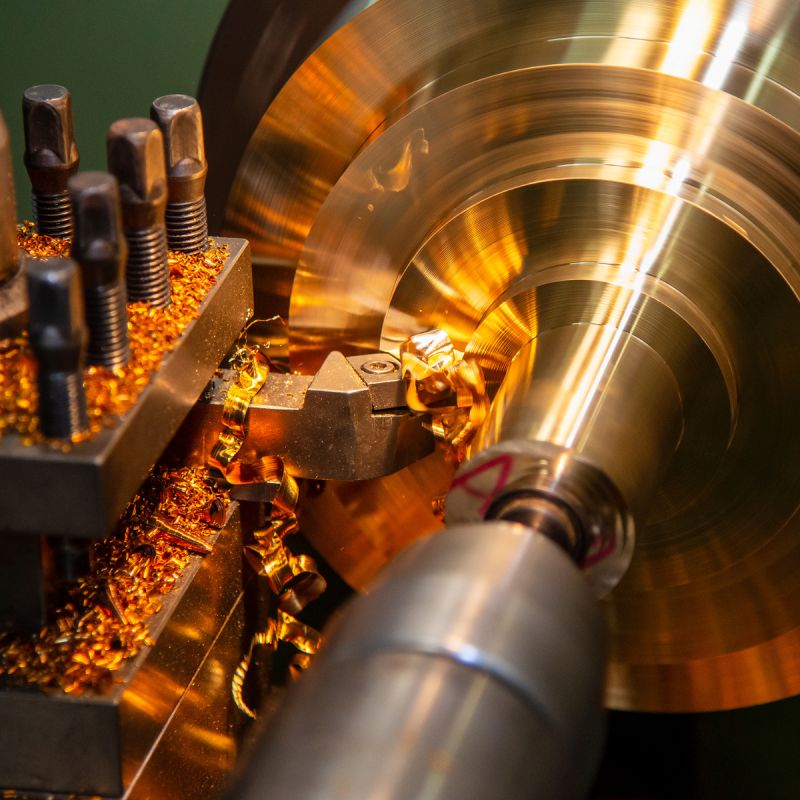

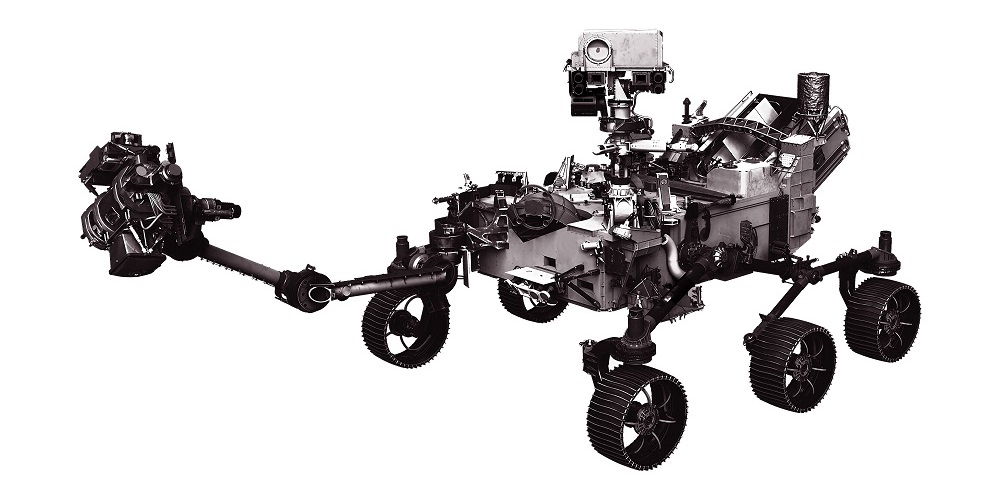

Cutting tool inserts are used in a wide range of machining and metalworking applications to perform numerous cutting, shaping, and finishing operations. They are used in a broad range of industries, including aerospace and defense, medical device and automotive manufacturing, composite material machining and you can even find cutting tool inserts on Mars! Inserts finished in a Vapormatt Tiger wet blasting machine are fitted to the drill on the Mars Rover.

The quality of cutting tool inserts is of paramount importance in the field of machining and metalworking. For the many reasons listed below, the performance, efficiency, and safety of machining operations heavily depend on the quality of the inserts being used.

Click on the subject area of interest for more information

Contact us to discuss how we can help improve your insert cleaning and finishing

Investing in high-quality cutting tool inserts pays off in terms of improved performance, longer tool life, enhanced safety, and increased productivity.

Given all the advantages of high-quality inserts, manufacturers typically prioritise sourcing them from reputable suppliers and adhere to proper maintenance and usage practices to maximise the benefits.

Contact us to discuss how we can help improve the quality and durability of your inserts

Finishing cutting tool inserts by wet blasting, also known as wet abrasive blasting or vapor blasting, offers several benefits that can contribute to improved tool performance, longevity, and overall machining quality. Wet blasting involves using a mixture of abrasive media and water under pressure to remove surface contaminants, refine surface finishes, and enhance the properties of cutting tool inserts. Learn how the wet blasting process works by visiting our What is wet blasting? page. Here are the main advantages:

Contact us to discuss how we can help improve your insert cleaning and finishing operation

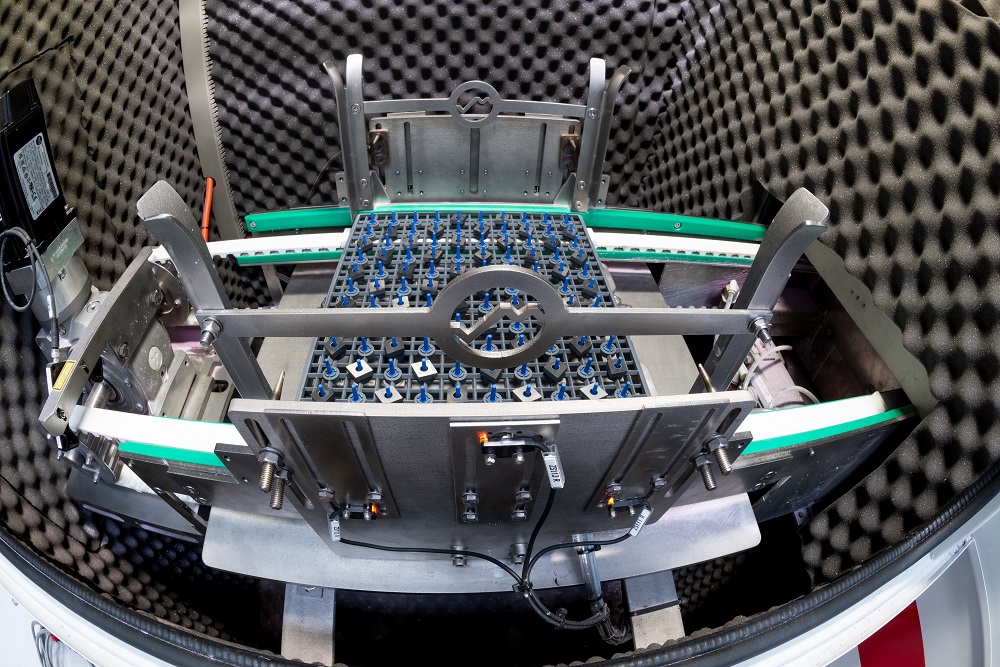

The world’s leading cutting tool insert manufacturers choose our wet blasting machines for their insert finishing. Our automatic Tiger and Tiger + wet blasting machines have firmly established themselves as the global gold standard for large scale insert manufacturers.

Our Tiger + machine has an additional blast chamber that allows two different finishing processes on a single run through the machine, or increased productivity if both chambers are set to perform the same function.

Watch videos of our standard Tiger, a Tiger that’s modified to be highly automated for insert pre-coating preparation, and our next-generation Tiger + designed for inserts with complex three-dimensional geometries.

Contact us to discuss how the Tiger or Tiger + can help improve your insert finishing operation

We don’t just cater for the largest insert manufacturers; we have an extensive range of automatic machines designed to process inserts no matter what size the manufacturer, from the smallest to the world's largest.

Suitable for replaceable inserts of varying geometries, our high precision cutting tool insert wet blasting machines are extremely controllable and reliably delivering a consistent finish every time.

Watch the videos below to see our mid range Cougar + and entry level Puma + automatic wet blasting machines processing pallets of cutting tool inserts.

Our Jaguar and Sablre machines sit midway between our Tiger / Tiger + and Puma + / Cougar + machines in terms of automation and capacity. Click on the relevant machine in the machine section below for more information.

Contact us to discuss how we can help improve your insert cleaning and finishing operations