Benefits of wet blasting

From consistency to eco-friendliness, wet blasting has numerous benefits when compared with other finishing processes.

To learn more about wet blasting click on the topics of interest below…

Contact us to discuss how wet blasting might benefit your operation

Vapor blasting, vapour blasting, aqua blasting, wet abrasive blasting and slurry blasting are simply alternative terms for wet blasting. Vapor blasting is a term commonly used for wet blasting in the automotive industry. ‘Vapor’ is the American English spelling, whilst ‘vapour’ is the British English spelling. Aqua blasting highlights the use of water in the process and slurry blasting emphasises the use of a water-abrasive mixture. Wet abrasive blasting is more of a general term describing any blasting process that involves both water and abrasive.

Hydro blasting is sometimes used interchangeably with wet blasting, although this can also refer to high-pressure water jetting without abrasives. Dustless blasting is a broader term that can include both wet abrasive blasting and other dust-reducing methods. Liquid honing is a term used in precision finishing applications. ‘Honing’ is a wet blasting application where cutting edges have an edge radius applied to them for improved durability, see the section on wet blasting applications below.

Contact us to discuss any aspect of your cleaning and finishing operation

Sir Frank Whittle inventor of the turbojet engine

Sir Frank Whittle inventor of the turbojet engineThe first wet blasting machine was invented by Norman Ashworth in the late 1940s whilst investigating surface treatments with Sir Frank Whittle during the development of the first turbojet engine.

Norman developed the concept of wet abrasive blasting as an improvement over traditional dry sandblasting, aiming to reduce dust, respond to the ban of silica in sand blasting, improve surface cleanliness and improve the quality and consistency of surface finishing.

His innovations led to the development of Vapormatt, one of the first companies specialising in wet blasting technology. The company is owned and run by the Ashworth family to this day.

Learn more about the history of wet blasting

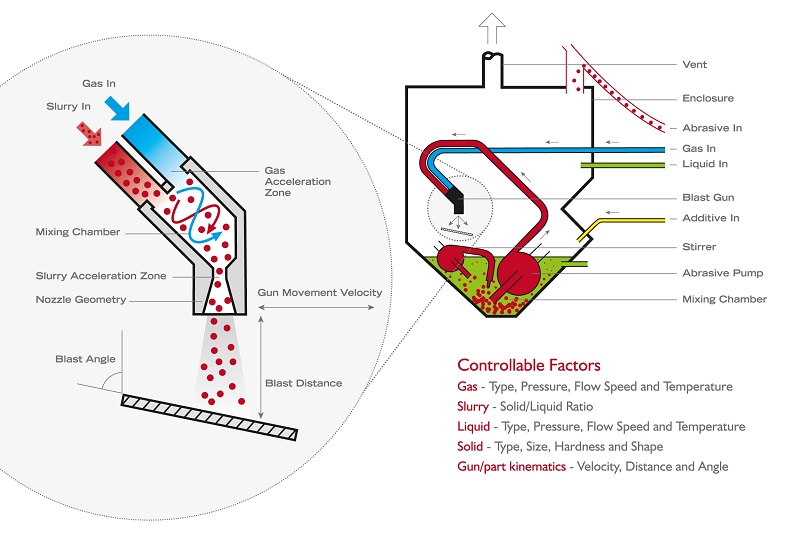

A slurry of water and fine abrasive media, glass beads, aluminium oxide, or silicon carbide for example, is prepared in the sump of the wet blasting machine.

The water and abrasive slurry is then delivered to a blasting nozzle under pressure using compressed air, which propels the mixture onto the target surface.

Grease, oils, burrs, oxidation and other contaminants are rapidly removed without damaging coated surfaces. Or, by adjusting the wet blast recipe of blast media, water and air pressure, paints and other coatings can be quicky removed, again without damaging the substrate.

Surfaces are simultaneously polished and if needed, prepared for further production processes like painting or PVD coating. If required, cutting edges can be honed for durability and surfaces peened for additional strength.

Unlike dry blasting, the presence of water reduces heat and friction, minimising surface damage and warping, making it ideal for delicate materials.

Contact us to discuss the suitability of wet blasting for your finishing operation

Unlike dry blasting, wet blasting uses a third element, water, to enhance the levels of surface finish that can be achieved. The benefit of including water is a much smoother and more consistent finish. In addition to producing a clean uniform finished surface in a single operation without damaging substrates, wet blasting is environmentally friendly and safe for operators.

Wet blasting is also more controllable than any other type of finishing process allowing operates to achieve the perfect finish on their components. We are world leading when it comes to the level of control users can achieve with the wet blasting process.

A range of abrasive medias can be used in our machines. The media used is determined by the type of effect or finish required. Typically, users opt for a silicon glass bead for a ‘polished’ finish or an aluminium oxide to achieve a ‘cutting’ effect that leaves a matt finish. However, various ‘special’ abrasive medias such as ceramic, plastics and stainless steel shot can also be used on particular applications. See our guide to abrasive medias to learn more, link at the bottom of the page.

Visit our ‘Benefits of wet blasting’ page for our finishing technologies comparison table

Vapormatt have chosen to build upon their technological advantage and opt to primarily serve industries needing a very high quality of wet blasting that gives a highly accurate surface finish. This allows us to work closely with high tech industries to constantly improve our processes.

Today, it provides the perfect finish on everything from medical implants and bandsaw blades to the composites used in Formula 1 cars.

Wet blasting is applicable to a wide range of industries and applications. Click on the links below to visit our dedicated industry pages.

Additive manufacturing - Surface finishing, powder removal from channels, peening, suface preparation for coatings

Additive manufacturing - Surface finishing, powder removal from channels, peening, suface preparation for coatings Aerospace MRO - Wet shot peening, paint stripping, preparation for NDT crack detection, preparation for re-coating

Aerospace MRO - Wet shot peening, paint stripping, preparation for NDT crack detection, preparation for re-coating Aerospace OEM - Wet shot peening blades, peperation for coating and bonding, preparation for NDT crack detection

Aerospace OEM - Wet shot peening blades, peperation for coating and bonding, preparation for NDT crack detection Alloy wheels - Repair and refurbishment, stripping and cleaning, SMART repairs, preservation of wheel integrity

Alloy wheels - Repair and refurbishment, stripping and cleaning, SMART repairs, preservation of wheel integrity Aluminium extrusion - Removal of caustic trace and residual aluminium, no damage to edges, preparation for nitriding

Aluminium extrusion - Removal of caustic trace and residual aluminium, no damage to edges, preparation for nitriding Bandsaw blades - Honing cutting teeth, peening gullets, cleaning, deburring and edge smoothing, preparation for coating

Bandsaw blades - Honing cutting teeth, peening gullets, cleaning, deburring and edge smoothing, preparation for coating Composites - Surface finishing without damaging delicate fibres, creation of ideal 'wet out' surfaces for coating and bonding

Composites - Surface finishing without damaging delicate fibres, creation of ideal 'wet out' surfaces for coating and bonding Cutting tool inserts - Deburring and cleaning, edge honing, peening, surface preparation for coatings, post coating finishing

Cutting tool inserts - Deburring and cleaning, edge honing, peening, surface preparation for coatings, post coating finishing Defence - Cleaning and finishing in one rapid operation, paint stripping and preparation for re-coating, geometry integrity

Defence - Cleaning and finishing in one rapid operation, paint stripping and preparation for re-coating, geometry integrity Dental - Dubbring dental implants, damage-free cleaning, biocompatible finishing, creation of perfect surfaces for coating

Dental - Dubbring dental implants, damage-free cleaning, biocompatible finishing, creation of perfect surfaces for coating Medical implants - Rapid contaminant removal, peening, perfect uniform surface preparation for optimum biocompatibility

Medical implants - Rapid contaminant removal, peening, perfect uniform surface preparation for optimum biocompatibility Medical instruments - Removal of burrs and contaminants, creation of non-reflective surfaces that are ideal for sterlisation

Medical instruments - Removal of burrs and contaminants, creation of non-reflective surfaces that are ideal for sterlisation Round shank tools - Cleaning, deburring and finishing in one operation, edge honing, peening, preparation for PVD coating

Round shank tools - Cleaning, deburring and finishing in one operation, edge honing, peening, preparation for PVD coating Wire and cable - Creation of surfaces for power transmission, cleaning prior to extrusion, grapite and heat scale removal

Wire and cable - Creation of surfaces for power transmission, cleaning prior to extrusion, grapite and heat scale removalIn addition to the industries listed above, wet blasting is applicable to the automotive, marine, food processing, electronics and semiconductor industries.

Contact us to discuss the applications of wet blasting for your industry

Wet blasting is a highly versatile finishing process with numerous applications for a wide range of different industries. It is also worth noting that multiple applications can often be carried out in a single operation, saving on handling and processing costs. Click on the links below to learn more about each application.

Contact us to discuss the applications you are interested in

Automatic wet blasting machines reliably deliver a consistent uniform finish to a surface every time. They are particularly well suited to the frequent processing of batches of similar components, delivering significant productivity improvements over manual wet blasting machines - especially when multiple cleaning and finishing processes are completed in a single operation. Our comprehensive range spans from our entry level Puma + automatic wet blasting machines to robotic machines like the Sabre that is designed to process components with highly complex geometries. All our machines can be used for any of the applications mentioned above.

Manual wet blasting machines are best suited to infrequent use or when the component being processed regularly changes, different sized composite components for example, or where there is just a few components in a batch. A number of our customers use them alongside their automatic machines for one off jobs or when testing the wet blasting process in preparation for an automatic machine. All our wet blasting machines are fully featured ensuring operators have full control over the wet blasting process. Our range of manual machines ranges from the highly popular and compact Vapormate to our Puma XL, which is designed for the processing of larger components.

From consistency to eco-friendliness, wet blasting has numerous benefits when compared with other finishing processes.

With our core focus on process control, our wet blasting machines lead the way when it comes to repeatable and reliable processing.

We are the original innovators of the wet blasting machine and continue to innovate to ensure our customers stay ahead of their competitors.

Wet blasting is a highly controllable finishing process, one of the key controllable variables in the process is blast media.

The health, safety and environmental benefits of wet blasting compared to the other main type of blast finishing, dry blasting.