Our tried and tested wet blasting machines (vapor blasting machines, or aqua blasting machines, to give them their other names) for round shank tool manufacturers, re-grinders and coating centres can complete multiple finishing processes in a minimal number of operations for significantly reduced tool handling costs.

Applications for our world leading technology are listed below and include our ability to edge hone (or edge round) more precisely than drag finishing. Click on the application or subject of interest for more information

Contact us to discuss your round shank tool cleaning and finishing requirements

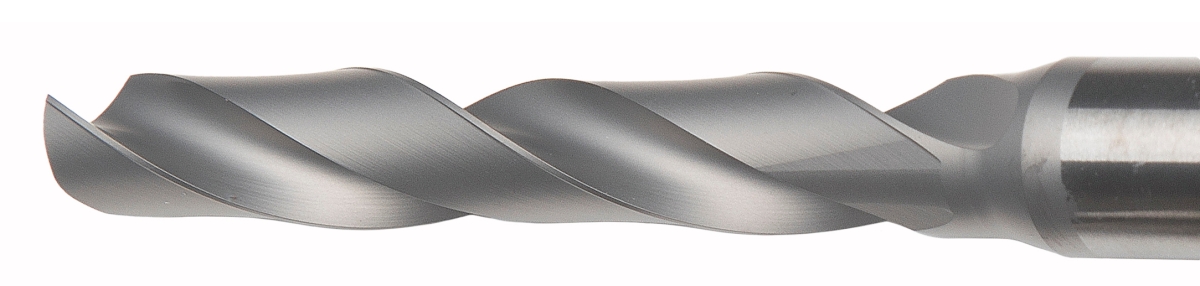

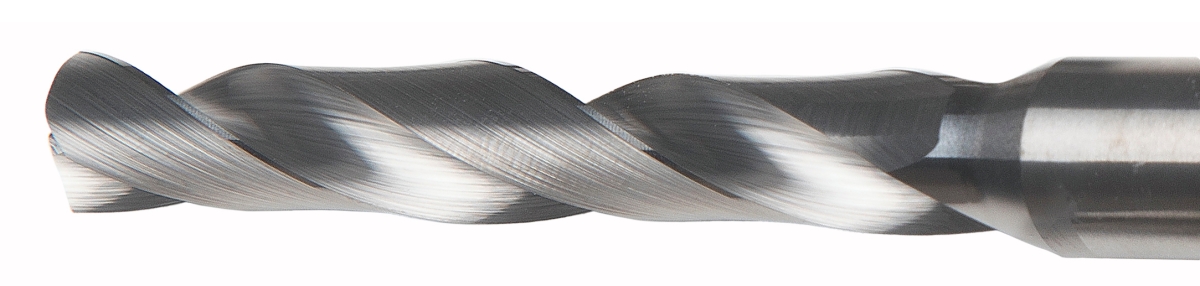

Encompassing drill bits, end mills, thread mills or taps, bullnose router bits, burrs, step drill bits, and others, round shank tools perform a wide variety of jobs.

The extra investment customers make in high-quality tools, especially carbide tools, reflects the performance and longevity they expect - including improvements in performance, durability, safety, cost efficiency, consistency of results and increased uptime.

For these reasons, customers typically turn to brands they trust to not let them down on quality.

It takes years or even decades to build a trusted brand, but that trust can be quickly lost if the tool performs below expectations.

Our wet blasting technology can help ensure your customers receive the quality they expect.

Contact us to find out how our wet blasting technology can improve tool quality

Wet blasting (vapor blasting, vapour blasting or aqua blasting, to give the process it's other names) rapidly and thoroughly removes contaminants, grease, oils, residues, and oxides from the surface of tools. A clean surface is essential for coatings, treatments, or subsequent manufacturing steps.

In the same process, tools are deburred and surface flaws are removed.

By eliminating surface flaws, wet blasting can improve the durability and resistance of round shank tools to wear and corrosion, extending their operational lifespan. The smoother surfaces that result from wet blasting can minimise friction and wear during the tool's use, contributing to better performance and longer life.

The option of combining cleaning and finishing processes to a single or minimal operations is one of the great advantages of our wet blasting technology. For example, cleaning, deburring, de-greasing and edge honing (or edge rounding) can be carried out in a single ‘edge preparation’ process.

Contact us to discuss how we can improve your edge honing operation

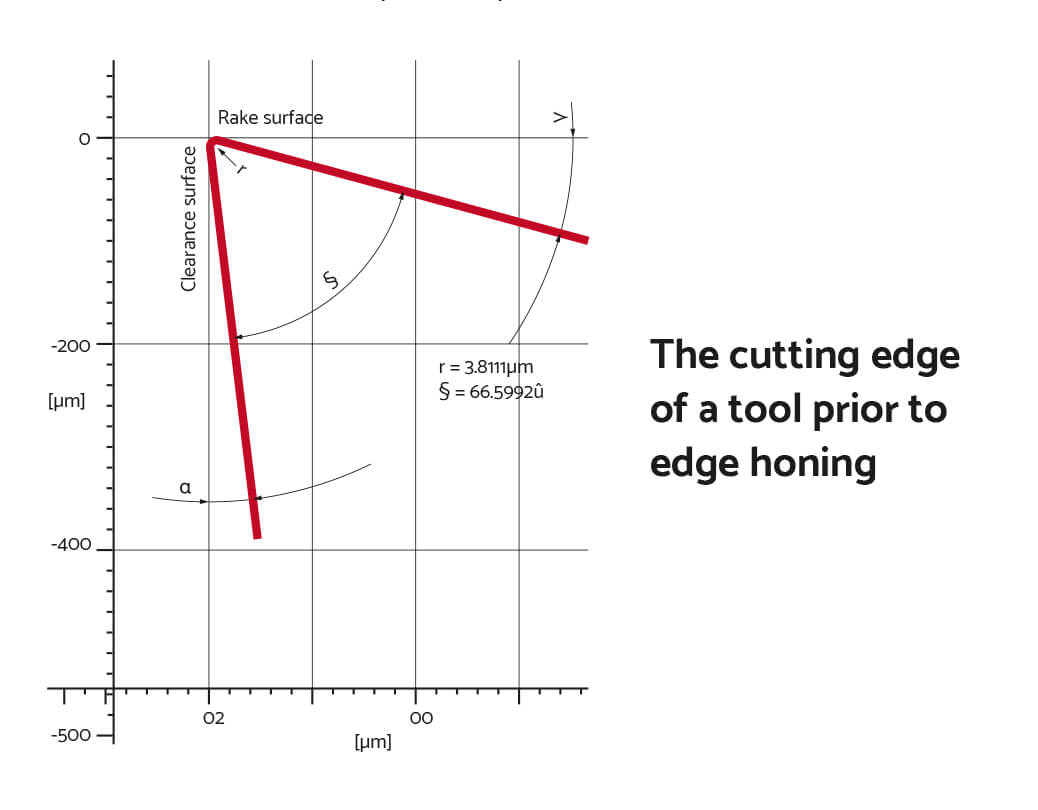

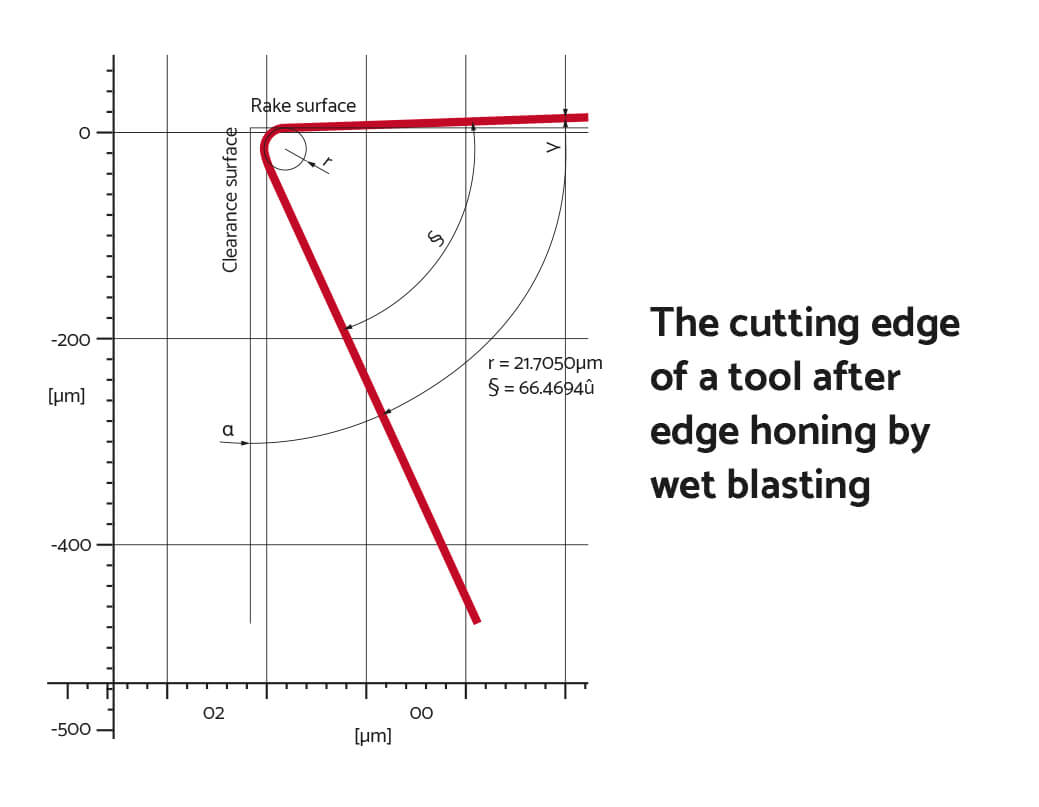

A measure of tool quality is the durability of the cutting edge. In the same way a highly sharpened pencil is prone to snapping, a tool’s cutting edge when highly sharpened can be easily chipped and damaged.

'Let our technical edge help improve your cutting edge'

The solution is to apply a specific edge hone (or rounded edge) that helps prevent the cutting edge from being damaged by chipping or curling and that also allows the tool to run at full production speed from new.

Wet blasting can apply this edge hone to a specific micrometre tolerance and profile, otherwise known as a K-factor, to suit the application the tool is designed for. Profiles can range from a waterfall hone with a K-factor greater than one to a reverse waterfall or trumpet hone with a K-factor of less than one.

The wet blasting process can apply an edge hone more accurately and consistently than other honing technologies like drag finishing.

Residual stress minimisation: Wet blasting imparts compressive stress on the drill bit's surface, which can reduce the likelihood of micro-cracks forming on the cutting edge. This stress reduction helps maintain the integrity of the edge, leading to more consistent chip formation - see the section below for more information about wet blasting's contribution toward the production of a perfect 'chip.'

Improved Fatigue Resistance: The reduction of surface stress also enhances the tool's fatigue resistance - essential for maintaining cutting efficiency over time, especially when cutting tougher materials.

'One of our customers was resharpening high-performance drills but was not edge-honing them. Using our automated Oncilla wet blasting machine, they applied a specific edge hone which increased tool life by five to seven times.'

So, as well as being highly relevant to tool manufacturers, our edge honing technology allows re-grinders to make old tools perform like new tools - or even better!

And a tool that stays sharp for longer means fewer tool changes and less downtime.

Contact us to discuss how we can improve your edge honing operation

The ability to adjust the K-Factor during the wet blast edge honing process is a technology we have developed and patented. You can read the patent via the link below

Read our Patent for adjusting K-Factor

The precise edge hone produced by wet blasting, as described in the section above, also allows the tool to generate an ideal 'chip' with an optimum depth and curl, resulting in longer tool life and a better finish.

Chip evacuation: The improved edge geometry facilitates better chip flow, reducing the chances of chip re-cutting and clogging, which can lead to heat buildup and tool failure. Efficient chip evacuation is critical for producing clean and consistent chips that are easy to remove from the cutting zone.

Reduced friction: The honed edge reduces friction between the tool and the workpiece, leading to smoother cutting action and more efficient chip evacuation. This helps in producing chips that are more uniform in size and shape, which is ideal for maintaining cutting stability and avoiding tool overload.

Reduced Built-up Edge (BUE): The smoother edge resulting from wet blasting reduces the tendency for material to adhere to the cutting edge (BUE formation). BUE can disrupt chip formation and lead to uneven cutting, so its reduction is beneficial for ideal chip production.

Reduced vibration: A honed edge can reduce cutting vibrations, leading to a more stable drilling process. Stability in drilling ensures that the chip formation process remains consistent, which is crucial for maintaining the desired chip shape and size.

Consistent edge: Wet blasting ensures a uniform edge profile across the entire cutting edge, which is critical for producing consistent chips. Consistent chip formation is vital for maintaining smooth drilling operations and avoiding issues like chip clogging.

The perfect edge can be generated for a specific target material, further increasing the value of the tool.

Contact us to discuss how we can improve your edge honing operation

A common area of quality concern for round shank tools is the successful application of a durable PVD coating. A highly reactive tool surface helps ensure the even and thorough application of coatings, ensuring best possible coating adhesion and subsequent wear resistance.

Wet blasting is exceptionally good at activating surfaces - more so than any other type of finishing process, producing an Ra surface roughness that is perfect for the application of coatings.

Finishing to a specific Ra is also important when it comes to drill bits, taps, or other types of round shank tools used in the medical industry as it is possible to finish tools to an Ra surface roughness that is ideal for effective sterilisation.

Thanks to automation the same perfect finish for coatings is applied to the entire body of the tool.

Contact us to discuss how we can help improve your coating operation

Opportunities to improve the quality of the tool continue after coating. Wet blasting after coating removes coating imperfections, like PVD coating droplets, to leave a uniform surface with an optimum Ra surface roughness for the cutting operation required from the tool.

Abrasive media choice: Fine abrasive particles are used that are carefully selected to be gentle enough to avoid damaging the underlying tool substrate while being effective at removing imperfections on the coating. The media can remove high spots, inconsistencies, or thin layers of unwanted material from the tool surface.

Controlled erosion: The wet blasting process allows for very controlled erosion of the coating. By adjusting the pressure, media type, and blasting angle, operators can target specific imperfections, such as uneven coating thickness, nodules, or rough areas, without stripping away the entire coating.

Surface refinement: Wet blasting not only removes imperfections but also smooths the overall surface of the coating. This is particularly beneficial for round shank tools, where a smoother surface can reduce friction during use, leading to better performance.

Improving consistency: The process helps to homogenise the surface finish of the coating across the tool, ensuring that any rough patches or areas with excessive coating thickness are evened out. This results in a more uniform coating that performs consistently during cutting operations.

Minimal material removal: Unlike more aggressive methods, wet blasting is gentle and precise, ensuring that the tool’s geometry, particularly on cutting edges, remains intact. This is crucial for round shank tools where maintaining precise dimensions and edge sharpness is essential for effective cutting performance.

Edge honing combination: Wet blasting can be adjusted to simultaneously hone the edges of the tool while removing imperfections from the coating. This dual action ensures that the cutting edges are both sharp and smooth, with the coating providing optimal protection and performance.

Surface smoothing: By removing imperfections and smoothing the coating, wet blasting reduces the likelihood of early coating failure due to cracks or delamination. A smoother, defect-free coating leads to less friction and wear during tool operation.

Increased cutting efficiency: Tools with a uniform, well-adhered coating and smooth surface finish tend to cut more efficiently, as there is less resistance during operation, leading to longer tool life and better quality cuts.

Contact us to discuss how we can help improve your coating operation

Coatings like PVD typically have an incumbent tensile stress that can lead to fatigue cracks which in turn reduce the durability of the coating. Wet blasting can be used to peen the coating, converting tensile stresses into compressive stresses and in turn, dramatically improve the durability of the coating and the life of the tool itself, especially in demanding applications.

The compressive stresses and the slight densification of the coating achieved through wet blasting peening can close up micro-pores and surface imperfections. This sealing effect helps to prevent corrosive agents from penetrating the coating and reaching the underlying tool material. With reduced permeability to corrosive environments, the coating is less likely to degrade over time, leading to longer-lasting protection for the tool.

Tools with peened coatings typically exhibit improved cutting efficiency due to the combined effects of better adhesion, increased hardness, and a smoother surface finish. This results in more precise cuts, less heat generation, and reduced tool wear. It also contributes to greater stability of the coating under operational stresses, reducing the likelihood of sudden coating failures that could impact tool performance.

Contact us to discuss how we can help improve your coating operation

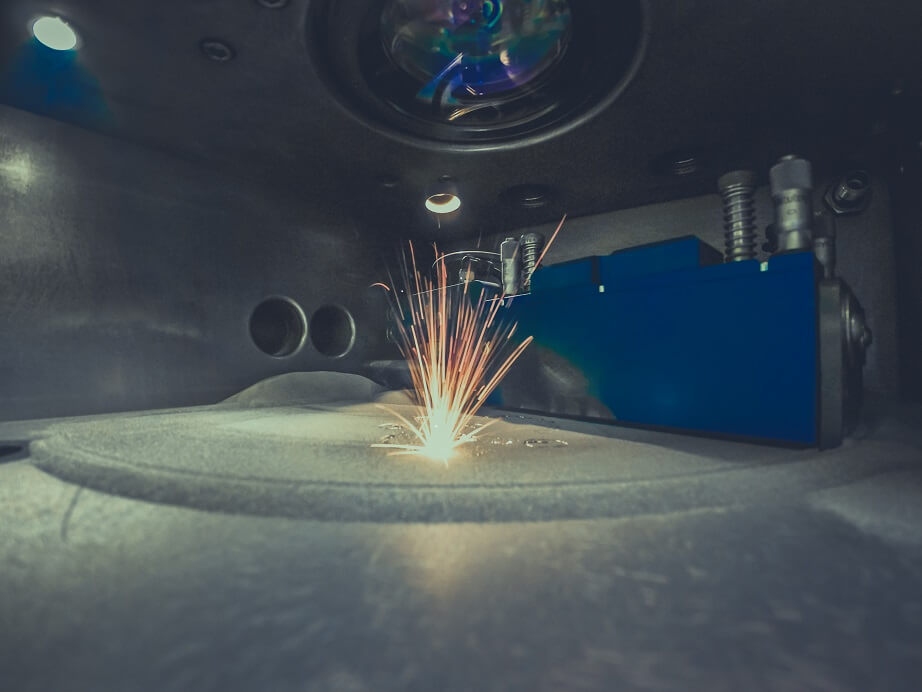

Thanks to advances in additive manufacturing (AM), round shank tools can be manufactured using AM technology. Our wet blasting technology is highly suited to finishing AM components in all sorts of different industries, including round shank tool manufacturing.

Finishing additive-manufactured (AM) round shank tools using wet blasting offers several key benefits, particularly in refining surface quality, improving mechanical properties, and enhancing the overall performance of the tools. Additive manufacturing often results in surface roughness, residual stresses, and other imperfections that can affect tool performance. Wet blasting addresses these issues in a highly effective way.

Learn more about the advantages of finishing AM components by wet blasting.

Contact us to discuss how we can help improve the finishing of your AM tools

In addition to the applications and benefits described above, wet blasting has numerous health, safety and environmental benefits too…

Noise Reduction: Wet blasting produces less noise compared to dry blasting, contributing to a quieter and less disruptive working environment.

Contact us to discuss your HSE requirements for your finishing operation

Controlling what comes out of the blast guns is essential for high quality consistent results. That applies to all applications, from cleaning and deburring to edge honing and surface preparation.

Vapormatt are second to none when it comes to controlling the consistency of output from blast guns.

The blast flow must always remain consistent and thanks to our world leading technical expertise and our patented technology we can achieve a consistent flow year in year out without change, even when components start to wear in the normal course of operation.

The consistency of blast combined with our automation significantly increases the productivity and quality of round shank tool finishing by ensuring the same high-quality finish for every tool, every time.

Watch our video on the controllable factors of wet blasting and how we control them...

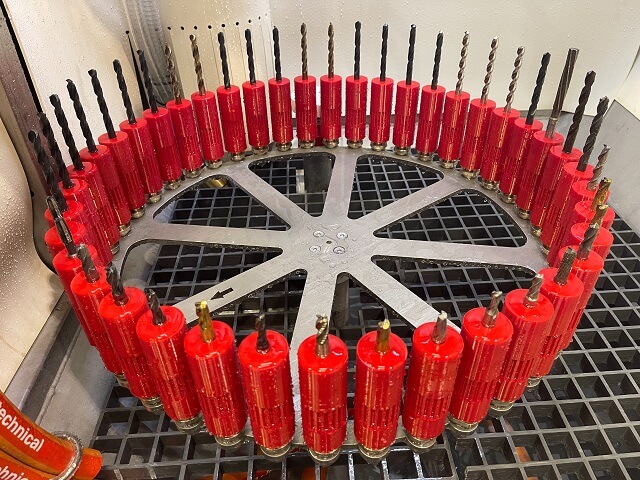

Designed specifically for the processing of round shank tools, our Oncilla, Oncilla Cub, and Puma + Vertical wet blasting machines (vapor blasting machines, or aqua blasting machines to give them their other names) are designed for efficiency, ease of use and to perform all the applications mentioned above.

Oncilla

The Oncilla automatic wet blasting machine is designed for premium tools where highly accurate process control and automation ensure an extremely high-quality finish every time. The robotic operation allows for one piece at a time to be processed so the wet blasting recipe of abrasive media, water, and air pressure can be refined, along with other controllable variables, for the perfect result for the tool's surfaces and cutting edges. An optional additional blast chamber allows for two finishing processes (for example, preparation for coating and edge honing) to be completed in one operation. Enhanced drying and other options can also be configured.

Oncilla Cub

The Oncilla Cub operates in a similar way to the Oncilla but has a fixed specification with one blast zone and basic rinsing and drying to help make it a lower cost solution.

Puma + Vertical

The Puma + Vertical wet blasting machine features a turntable with multiple satellites around its circumference, up to 42. Each satellite holds a tool, so multiple tools can be processed at the same time, making it a highly productive machine. The automated vertical action of the blast head and rotation of the satellites ensure complete 360-degree finishing.

All three machines are designed with ease of maintenance in mind and our filtration system ensures spent media is removed from the process leaving good quality blast media to create the required finish.

Contact us to discuss the most suitable wet blasting machine for your tool finishing needs

In a crowded and highly competitive market, customers seeking high quality round shank tools will look to the brands they know and trust. Wet blasting can help ensure your tools repeatedly deliver the high quality expected from your brand.