Wet blasting (also known as vapor blasting, vapour blasting or aqua blasting) is highly effective at cleaning and finishing a wide range of wire and cable products. Applications are numerous ranging from cleaning feeder wire prior to extrusion and the removal of graphite and heat scale to the application of a non-specular finish on overhead power cable.

Click on the subject area relevant to you wire and cable operation to lean about the associated wet blasting applications and benefits.

Contact us if you already know your wire and cable wet blasting requirements

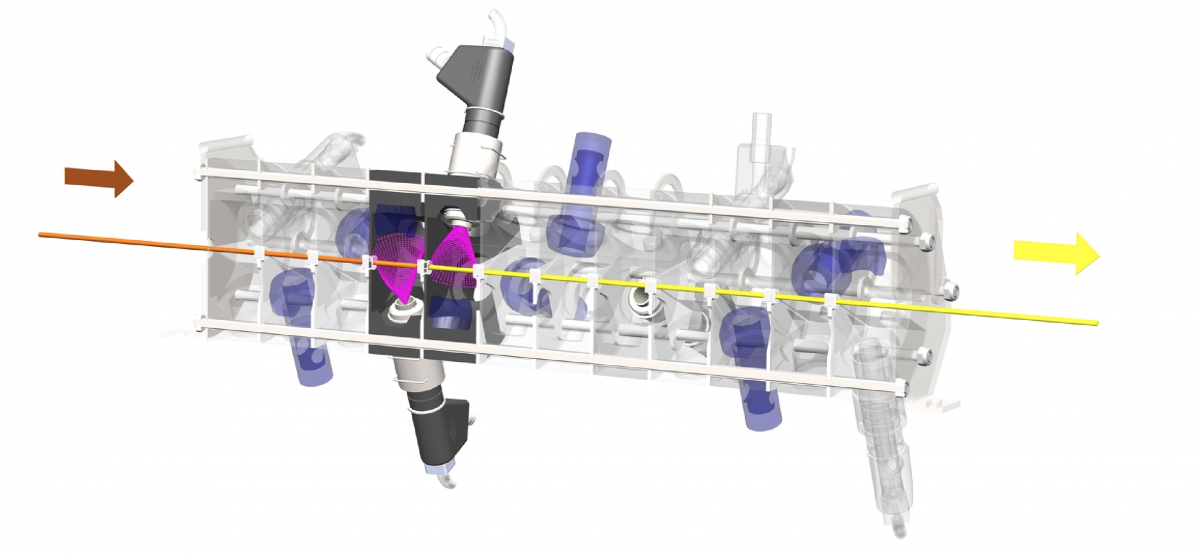

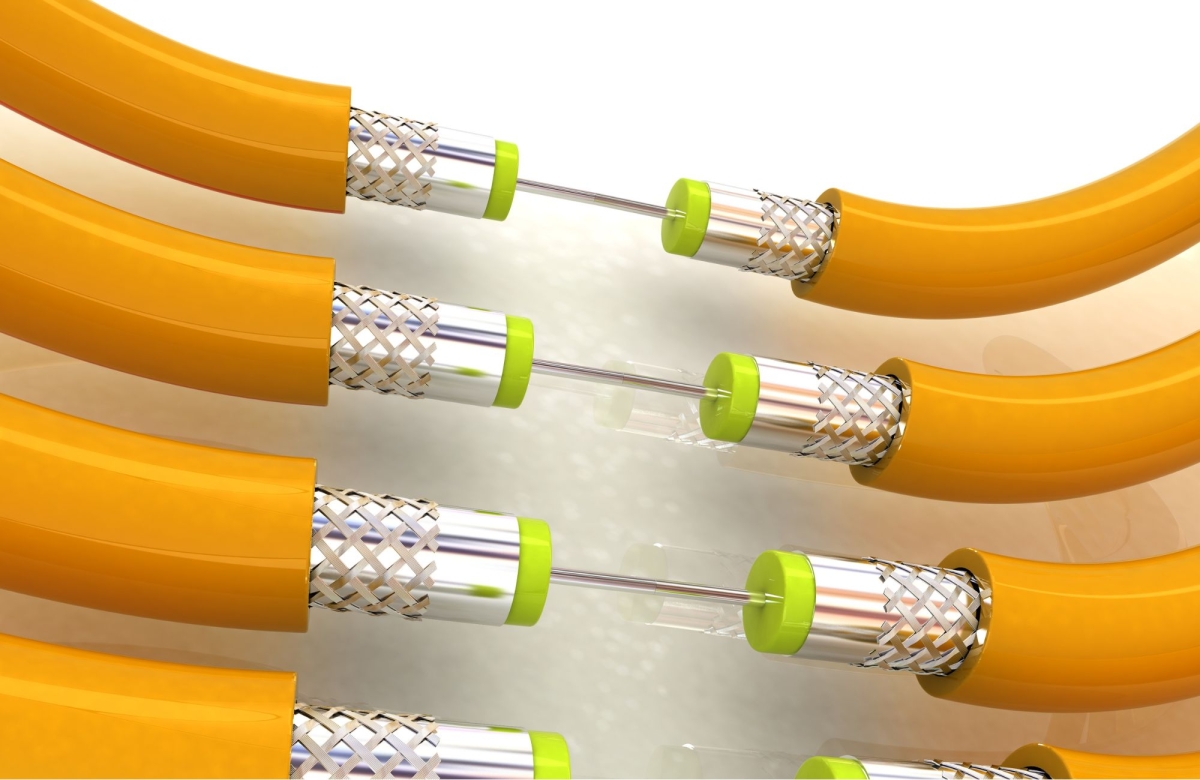

The Vapormatt Profelis automatic wet blasting machine

The Profelis wet blasting machine (or vapor blasting machine, or aqua blasting machine) is specifically designed for the surface finishing of wires, cables, round bars and other types of continuous products like bandsaw blades.

At the heart of the Profelis is a specially designed blast gun manifold. Four powerful blast guns are located at 90 degree angles to give complete 360 degree uniform finishing to a specific Ra surface roughness tolerance.

This highly effective configuration of blast guns in the manifold can be boosted further by specifying eight blast guns located at 45 degree angles for maximum productivity.

The versatile Profelis is capable of processing wire 1mm (0.04") in diameter to cable 54mm (2.13") in diameter

The Profelis is designed to work in-line with existing manufacturing lines, further improving productivity – especially when compared with pickling and dry blast finishing operations that are usually off-line from the main production line.

Rinsing and drying is included within the Profelis to ensure all blast media is removed from the wire or cable and then rapidly dried to help prevent oxidation and prepare the wire or cable for the next production process. If needed, inhibitors can be added to the blast slurry as an additional oxidation prevention measure.

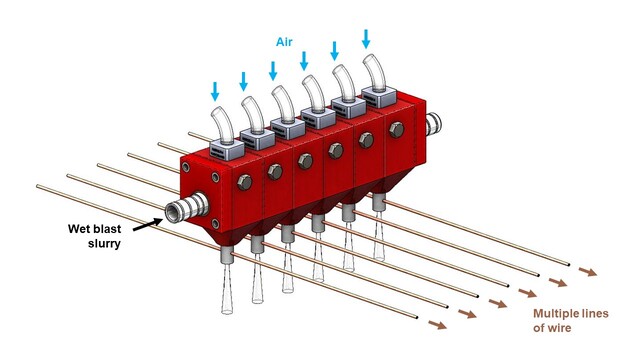

Blast manifold of the Profelis automatic wet blasting machine

Visit the automatic Profelis wet blasting machine page and download the tech spec.

Contact us to discuss how the Profelis can help your operation

All sorts of wire and cable products benefit from having a wet blasted (otherwise known as vapor blasted or aqua blasted) finish including:

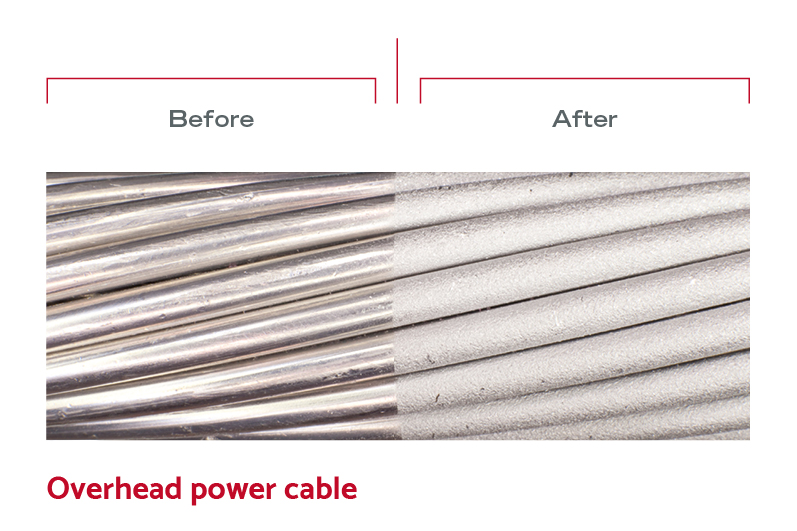

Essential for transmitting power over vast distances, overhead power cable needs to transmit electricity as efficiently as possible to help reduce running costs.

As well as thoroughly cleaning the cable, removing all contaminants, wet blasting (or vapor blasting, or aqua blasting, to give the process its other names) overhead cable creates a non-specular finish - which depending on the power cable manufacturer you talk to is also known as a de-glared, de-glazed, or de-glittered finish.

A non-specular, or de-glared, finish gives the cable higher emissivity (approx. 0.8) compared to the specular finish of an untreated cable (approx. 0.5)

Higher emissivity leads to more heat being emitted at the same air temperature. So, a cable with higher emissivity, in the same environmental conditions, with the same structure and current range, operates at lower temperatures as it can more easily emit excess heat.

And a power cable operating at a lower temperature typically has a greater ampacity compared to a cable operating at a higher temperature. Hence power cables with a non-specular, or de-glared, finish are more efficient at carrying electricity compared with unfinished cables with a specular finish.

An increase in current carrying capacity of around 5% can be achieved due to the increase in surface emissivity.

Overhead power cables with a non-specular, or de-glared, finish have the additional advantage of reduced visual impact, thanks to their matt appearance compared to shiny unfinished cable, in fact, a non-specular, or de-glared, finish is a pre-requisite for overhead power cable on US Federal land.

When dry blasted cables are unpacked ready for installation, there can be a considerable amount of residual dust from the blasting process, necessitating the need for face masks and other protective clothing. There is no residual dust with wet blasting.

Read our white paper which goes into a lot more detail on the subject.

Contact us to discuss your power cable finishing needs

Wet blasting is an ideal method for cleaning and finishing wire before Conform extrusion, offering several important advantages over other cleaning techniques. It effectively removes oxides, scale, and residual lubricants from the wire surface, providing a clean, defect-free feedstock essential for consistent, high-quality extrusion. The process produces a uniform, satin-like surface finish without significantly altering the wire’s dimensions, which is critical in precision Conform applications.

The presence of water in wet blasting reduces heat generation and eliminates airborne dust, creating a safer, cleaner working environment. Additionally, it enhances lubricant adhesion on the wire surface, improving downstream extrusion performance and protecting Conform tooling from contamination and premature wear. Wet blasting also offers precise control over cleaning parameters, ensuring consistent, repeatable surface preparation. Environmentally, it’s a cleaner process, with closed-loop systems that minimise media loss and water consumption while prolonging the life of both the wire and the extrusion tooling.

Contact us to discuss your wire for conform extrusion cleaning and finishing needs

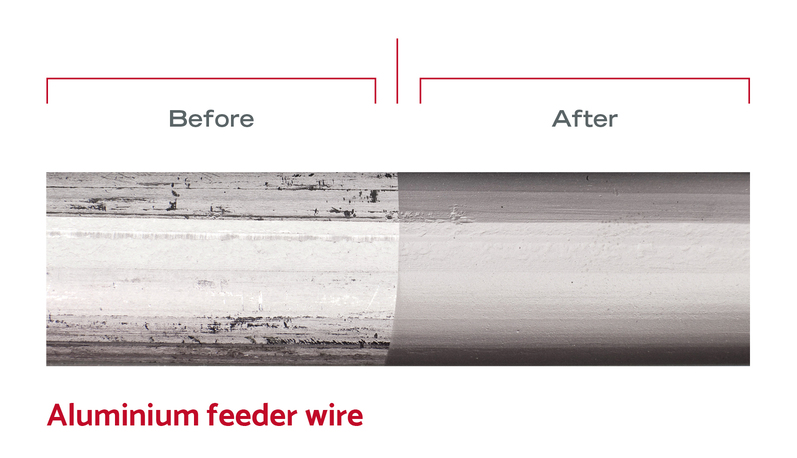

Aluminium wire is used in various applications due to its favourable properties, like its lightweight, durability, recyclability, good conductivity, and being relatively inexpensive compared to other metals like copper.

No matter what the application, high quality aluminium wire needs to be clean and free from imperfections. Wet blasting cleans the surface removing all contaminants and oxides, leaving feeder wire perfectly clean for extrusion.

It also produces a smoother surface finish by cushioning the impact of abrasive particles with water. This reduces the risk of surface damage and results in a more uniform finish that is free from imperfections and is better for extrusion because…

Contact us to discuss your aluminium feeder wire finishing needs

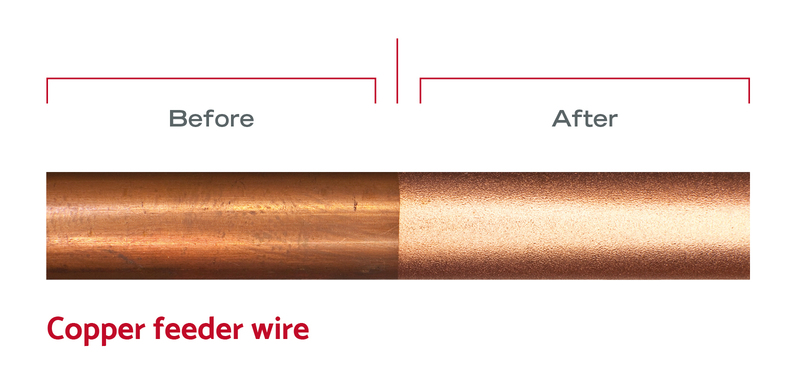

Copper wire is widely used in electrical and telecommunications applications due to its excellent electrical conductivity, flexibility, durability, and resistance to corrosion.

Wet blasting cleans and finishes copper feeder wire in one operation, removing imperfections, oxides, scale and other contaminants before it is drawn into the extrusion process.

The process produces a uniform and consistent surface finish, especially when compared with dry blasting. It is also less aggressive than dry blasting, which helps maintain the structural integrity of copper wire by preventing pitting or other surface damage.

The contaminant free and uniform finish helps ensure maximum strength, conductivity and corrosion resistance of the final copper wire product.

Contact us to discuss your copper feeder wire finishing needs

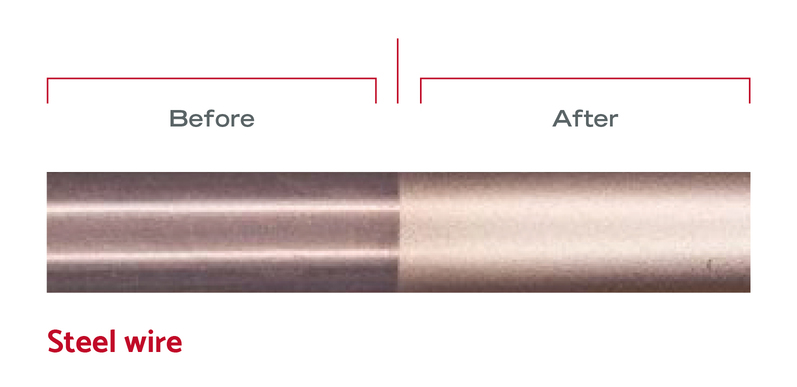

Steel wire has a vast range of applications in the construction, manufacturing, packaging, agricultural, automotive, medical and other industries.

Wet blasting cleans steel wire leaving a uniform surface entirely free from graphite, oxides, scale and other contaminants in preparation for forming, machining and heat treatment.

Clean and uniform steel wire is a better conductor, more resistant to corrosion, stronger and safer.

The process can also produce a range of different finishes depending on the specific aesthetic or functional requirements. This includes surfaces that are perfect for the adhesion of coatings and paints.

Contact us to discuss your steel wire finishing needs

Wet blasting is an effective and reliable method for cleaning and finishing high-tech wire, especially in industries like aerospace, medical devices, and electronics where surface purity and precision matter. It removes oxides, lubricants, and fine contaminants while producing a uniform, satin finish that improves coating, plating, and lubricant adhesion — all without altering the wire’s critical dimensions. The process also generates minimal heat and eliminates airborne dust, making it safer for both operators and clean manufacturing environments.

Another key advantage is its precise control over cleaning parameters, ensuring consistent, repeatable results essential for regulated, high-performance applications. Wet blasting’s gentle, controlled action protects delicate, heat-sensitive alloys and minimizes downstream defects. Additionally, its eco-friendly, closed-loop systems reduce media loss and water use, making it a clean, efficient, and sustainable choice for preparing advanced wire products.

Contact us to discuss your high-tech wire cleaning and finishing needs

Wet blasting is a highly effective method for cleaning and finishing memory wire, Nitinol for example. It removes surface contaminants like oxides, heat treatment scale, and manufacturing residues without aggressively removing material or affecting the wire’s critical dimensions. This makes it particularly well-suited for precision applications where dimensional accuracy is essential.

The process creates a smooth, uniform, satin-like finish that enhances both the appearance and performance of the wire, which is especially important for medical applications. By using a water-based abrasive mixture, wet blasting minimises the risk of introducing micro-cracks or surface stresses, helping to preserve the material’s fatigue strength and corrosion resistance.

Additionally, wet blasting improves the wire’s surface condition for coatings or subsequent treatments, promoting better adhesion and more consistent results. It also produces less airborne dust than dry blasting, making it a cleaner, safer option for sensitive manufacturing environments, such as those found in medical device production. Overall, wet blasting offers a precise, reliable, and environmentally friendly solution for finishing memory wire components.

Read our case study on wet blasting medical Nitinol wire to meet strict quality standards.

Contact us to discuss your memory wire cleaning and finishing needs

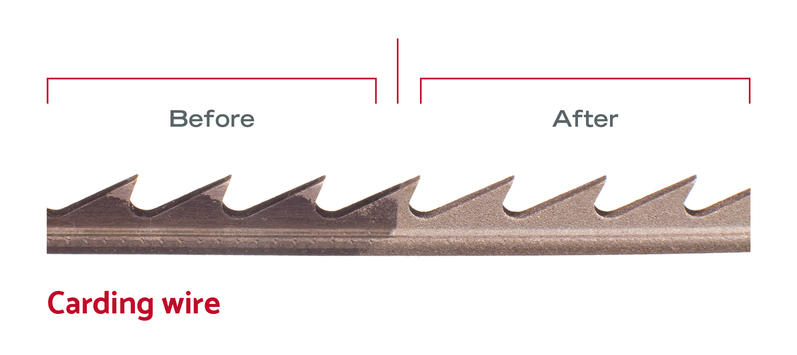

Carding wire is a toothed metal strip used on rollers in carding machines to disentangle, clean, and align fibers like wool, cotton, or synthetics. It helps separate clumps, remove impurities, and prepare fibers for spinning or further processing. It can also be used in other industries as well, for example, during the production of filters, gaskets, and other similar components. Clean carding wire can help improve the quality of yarns, prevent the spread of contamination and extend the life of carding machines.

Wet blasting removes all heat treatment discolouration and burrs from carding wire whilst carding teeth are precisely edge honed for additional durability. Heat scale and grease is also removed. If you want to learn more about edge honing, visit our dedicated application page.

Contact us to discuss your carding wire finishing needs

Used to transmit vast amounts of information for thousands of miles, submarine communication cable features layers of tough outer protection to ensure continued uninterrupted transmission.

Wet blasting submarine communication cable prior to sheath application effectively removes surface contaminants, oxides, and processing residues, whilst simultaneously producing a uniform, micro-textured surface profile. This surface roughness enhances mechanical interlocking and adhesive bond strength between the cable’s outer metallic or polymeric layers and subsequent sheath materials.

Compared to dry blasting, wet blasting reduces the risk of static discharge, dust contamination, and heat-related surface damage, ensuring better process control and long-term cable durability in harsh subsea environments.

Contact us to discuss your submarine communication cable finishing needs

Wet blasting (or vapor blasting, or aqua blasting to give the process its other names) has more controllable variables than any other type of surface finishing.

Such a comprehensive range of controllable variables allows manufacturers to achieve the perfect finish on their wire or cable products.

Automation then delivers that desired finish every time via the touch of a button on the Profelis’ simple to use colour HMI.

Another factor critical for consistent high-quality results is controlling what comes out of the blast guns.

Vapormatt is second to none when it comes to controlling the consistency of output from blast guns.

The blast flow must always remain consistent and thanks to our world leading technical expertise, our patented technology and regular maintenance we can achieve a consistent flow year in year out without change, even when components start to wear in the normal course of operation.

Watch our video on the controllable factors of wet blasting and how we control them...

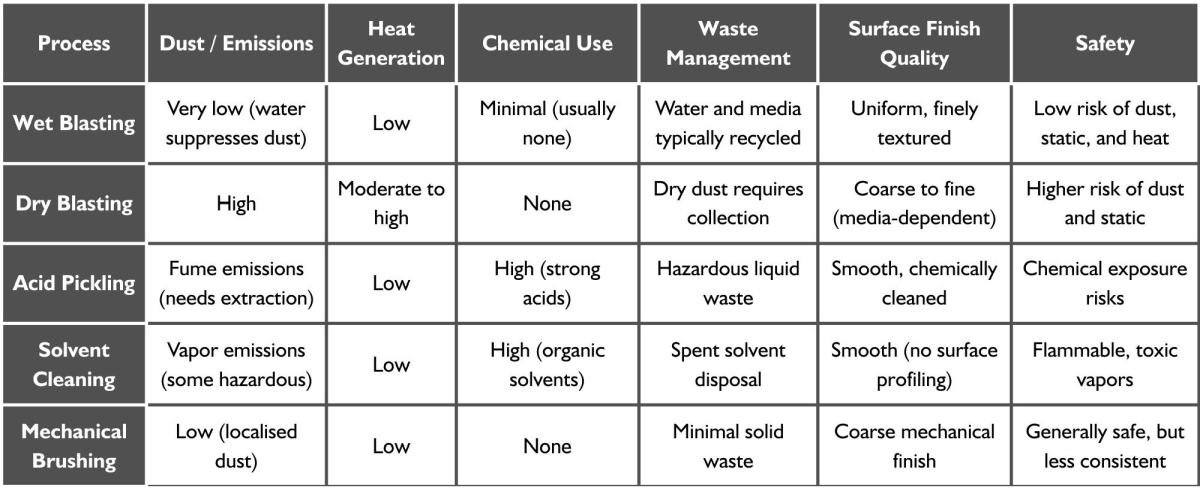

Wet blasting is considered safer and more environmentally friendly for wire and cable cleaning than most other finishing processes because it suspends abrasive media in water, which suppresses dust, reduces airborne particulate exposure, and minimises static build-up — important for preventing hazards in electrical and cleanroom environments. The water also acts as a lubricant and coolant, reducing heat generation that could damage sensitive wire and cable materials.

Environmentally, wet blasting recycles blast media and water in a closed-loop system, generating less waste and avoiding the use of harsh chemical solvents common in processes like acid pickling or solvent degreasing. It produces fewer emissions, limits environmental discharge risks, and offers better containment of removed contaminants, making disposal safer and regulatory compliance easier.

Cleaning and surface finishing methods comparison

Our micro gun technology is especially efficient when it comes to the use of compressed air, frequently the costliest component of the wet blasting process. So efficient in fact, we’ve patented it.

Another benefit is that micro guns can run together with a common slurry feed, so multiple lines of wire can be processed at the same time for maximum efficiency and productivity.

Learn more about micro-gun technology in our white paper.

Contact us to discuss how our micro gun technology can help your operation

Highly controllable and automated to provide precisely the finish required every time and with complete in-line 360 degree environmentally friendly and safe finishing, the Profelis wet blasting machine represents a major step forward in the finishing of wire and cable products.

Contact us to discuss how our technology can help your wire and cable finishing operation