Aircraft wheels are some of the most highly stressed components on an airframe. Preparing them correctly for non-destructive testing (NDT) is critical for safety, reliability, and cost control.

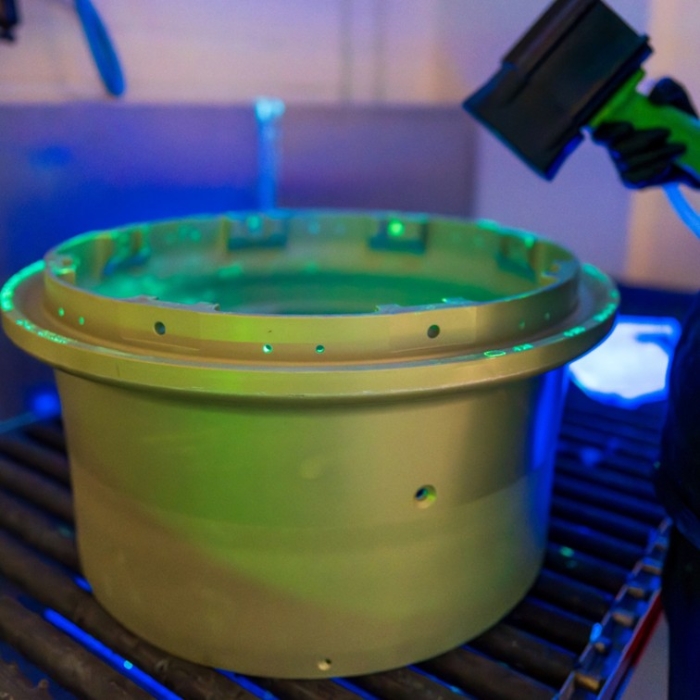

Wet blasting is recognised as the most effective method for paint stripping and surface preparation of aircraft wheels prior to NDT.

What it does...

• Removes paint, coatings, sealants, and in opeation contaminants in a single operation

• Prepares surfaces before MPI, DPI, FPI, ECT and other NDT inspections

• Delivers a final unform surface that is perfect for re-coating

Why it stands out...

• Produces a clean, uniform, satin finish that enhances crack visibility

• Non-aggressive process that preserves base material and critical dimensions

• Does not smear or peen over cracks

• No risk of media embedment, which can mask defects or contaminate surfaces

• Reduced heat generation, protecting metallurgical integrity

• Environmentally cleaner process with effective containment of media and waste

Compared with traditional dry blasting, wet blasting offers several clear advantages:

• Lower surface damage risk - Dry blasting can peen or erode aluminium and magnesium alloys, whereas wet blasting cushions the impact.

• Improved NDT reliability - Dry blasting may smear or peen material over defects; wet blasting cleans without closing cracks.

• Dust-free operation - Wet blasting eliminates airborne dust, improving operator safety and facility cleanliness.

• Consistent repeatability - Wet blasting delivers predictable results across complex wheel geometries.

In an industry where inspection accuracy directly impacts airworthiness, the NDT preparation method matters. Wet blasting supports better inspections, longer component life, and more controlled maintenance processes.

If you are reviewing your wheel overhaul or NDT preparation processes, it may be time to look closely at Vapormatt wet blasting.