If you’re in the business of manufacturing end mills, drills, or taps, surface prep is a critical step. That’s where the Vapormatt Puma+ Vertical (with satellites) stands out.

Here’s why it’s outpacing other wet blasting systems in the field:

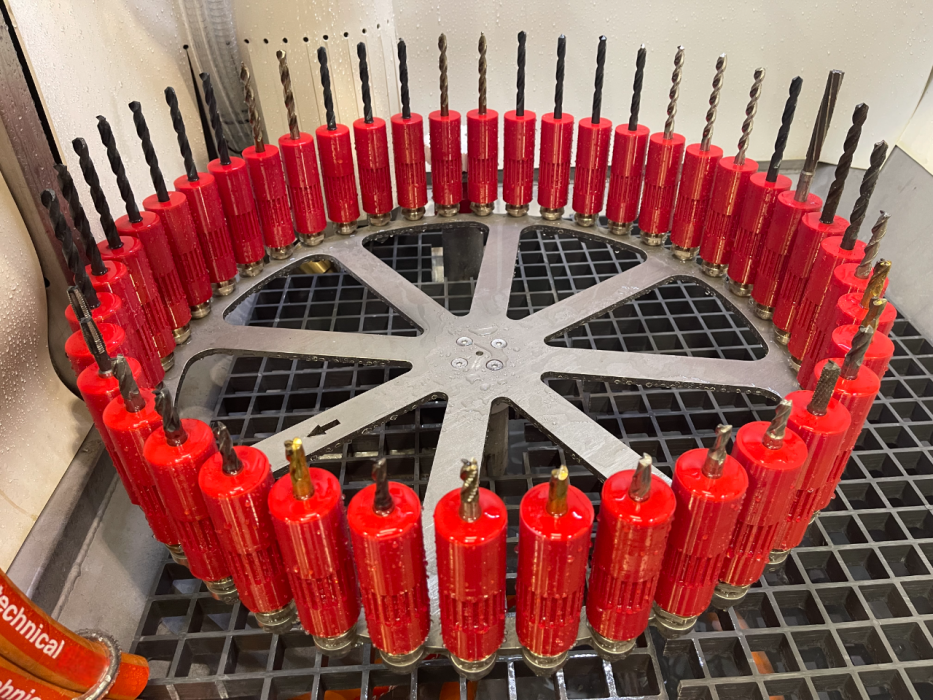

✅ Tailored for round shank tools - Designed specifically for tools from 3mm to 25.4mm diameter and up to 300mm long — up to 42 tools per cycle.

✅ True 360° coverage with Z-axis motion - Dual nozzles on a vertical oscillating arm + satellite rotation = uniform, repeatable results. Perfect for edge prep and coating adhesion.

✅ Recipe-driven automation - Fully programmable cycles (Z-speed, index timing, dwell) ensure consistent results with minimal operator input.

✅ Compact. Clean. Efficient - A compact-size footprint with integrated rinse, dry, and filtration systems keeps the process efficient and workshop-friendly.

✅ Built-in Industry 4.0 connectivity - Real-time diagnostics, cloud recipe management, and full process data logging make this machine ready for smart manufacturing environments.

Compare that to many competitor systems — static nozzles, batch barrels, manual cycles — and it’s clear why the Puma+ Vertical is in a class of its own.