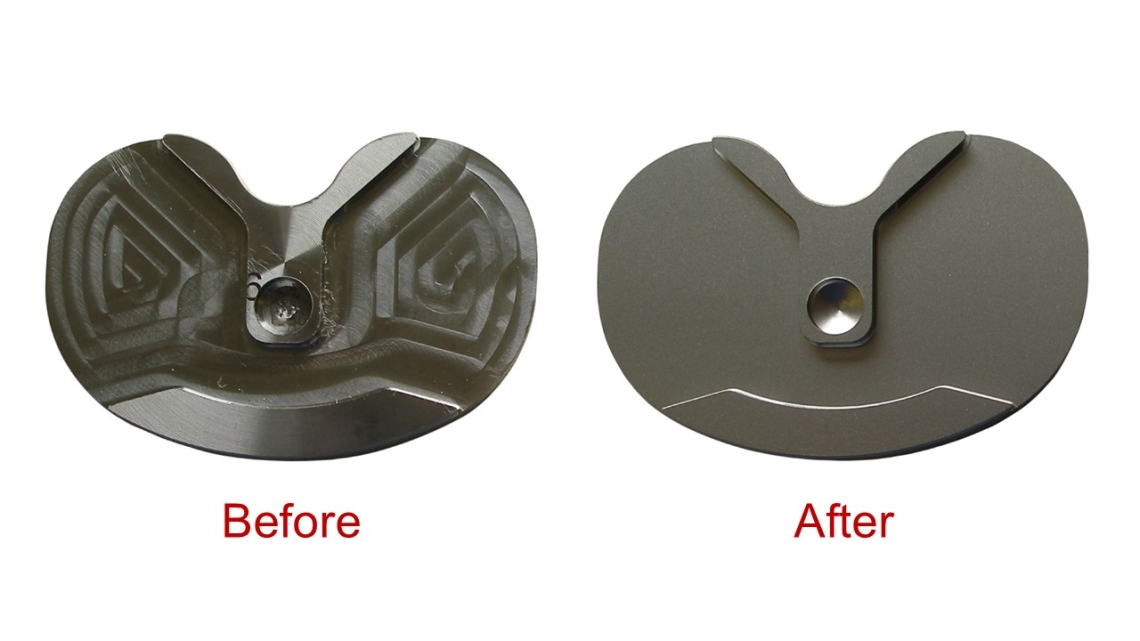

In orthopaedic manufacturing, achieving precise, consistent, and biocompatible surface finishes is critical — especially for complex medical implants like knee prostheses. While many facilities still rely on mechanical polishing, vibratory finishing, or dry blasting, wet blasting is gaining serious traction. Here’s why:

✅ Superior surface consistency: Wet blasting delivers highly uniform, isotropic finishes with excellent Ra control — essential for both articulating surfaces and porous-coated regions.

✅ Cleaner, contamination-free process: With no airborne dust and no risk of abrasive embedding, wet blasting is better suited for validated medical environments where implant cleanliness is non-negotiable.

✅ Enhanced process control: Adjustable wet blast slurry composition, pressure, and nozzle positioning allow for precise surface engineering — whether you're refining a 3D-printed implant or smoothing a cobalt-chrome femoral component.

✅ Ideal for complex geometries: Wet blasting preserves contours and edges better than dry blasting or aggressive polishing, making it perfect for intricate knee implant designs.

✅ Environmentally safer and easier to automate: Closed-loop systems reduce media waste, lower dust emissions, and integrate smoothly into automated finishing cells.

If your finishing processes still rely heavily on dry blasting or vibratory tumbling for medical implants, it might be time to explore wet blasting’s advantages — especially as implant designs and regulatory demands evolve.