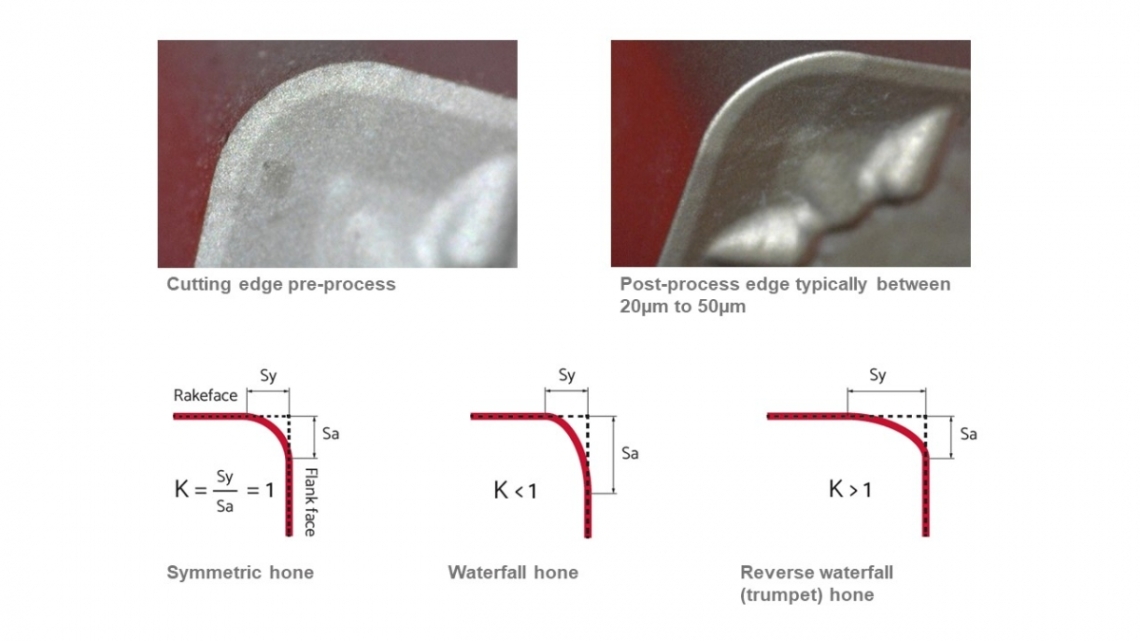

The K Factor is a dimensionless number that characterises the honed edge shape of a cutting edge. Defined as:

- K = +1 Gives a waterfall shaped hone - typically better for edge strength, tool life

- K = -1 Gives a trumpet shaped hone - sharper, but less durable

- K = 0 Gives symmetrical shaped hone

Different shaped hones suit different cutting applications. It’s particularly relevant to high-precision cutting tools like drills, end mills, and inserts — but is also increasingly used in advanced bandsaw blade production, especially for high-performance applications like aerospace alloys or high-nickel steels.

Wet blasting can control the edge hone shape, K factor, by:

- Adjusting blast angle and position relative to the tool faces

- Modifying dwell time distribution along the edge path

- Selecting media size, shape, and pressure to control cut aggressiveness

- Programming nozzle motion to bias material removal where needed

Wet blasting is superior to other finishing methods for producing a specific K factor because it enables fine control over edge geometry without introducing heat or microcracks, unlike grinding or brushing.

Wet blasting's ability to uniformly shape complex contours using adjustable media, pressure, and angles makes it uniquely capable of achieving precise waterfall or trumpet edge profiles, or anything in between, with consistent repeatability.

Learn more about the applications and advantages of finishing bandsaw blades by wet blasting on our dedicated industry page.