Wet blasting has proven to be particularly well suited to medical and dental implants because it balances surface functionality with process control.

Key reasons it works so well:

• Controlled surface texture - Wet blasting creates a consistent, repeatable surface that supports osseointegration without aggressive material removal.

• Clean, contamination-free processing - The use of water suppresses dust and heat, eliminating the risk of embedded media or surface damage.

• Gentle on complex geometries - This is especially valuable for fine features, internal channels, and thin sections.

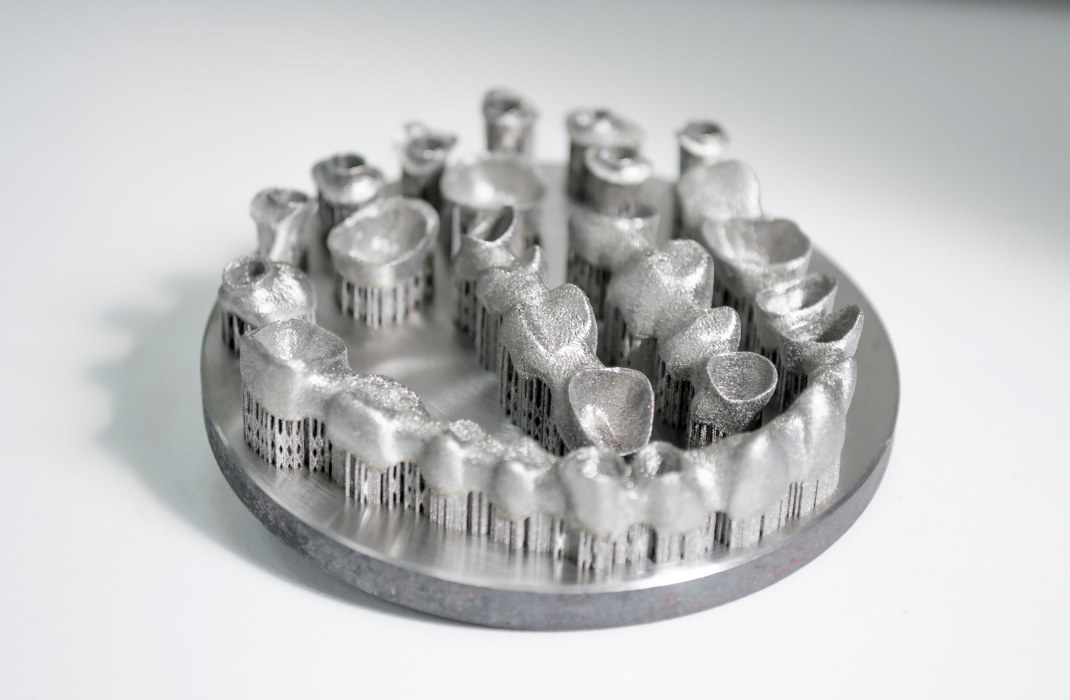

• Compatible with modern manufacturing routes - Additively manufactured implants often have complex lattices and rough as-built surfaces. Wet blasting allows these to be refined and thoroughly cleaned while preserving the design intent.

For dental implants in particular, the ability to tune surface roughness while maintaining tight tolerances makes wet blasting an attractive and reliable option.

As implant designs continue to evolve, especially with additive manufacturing, surface finishing methods that offer precision, cleanliness, and repeatability will only grow in importance.