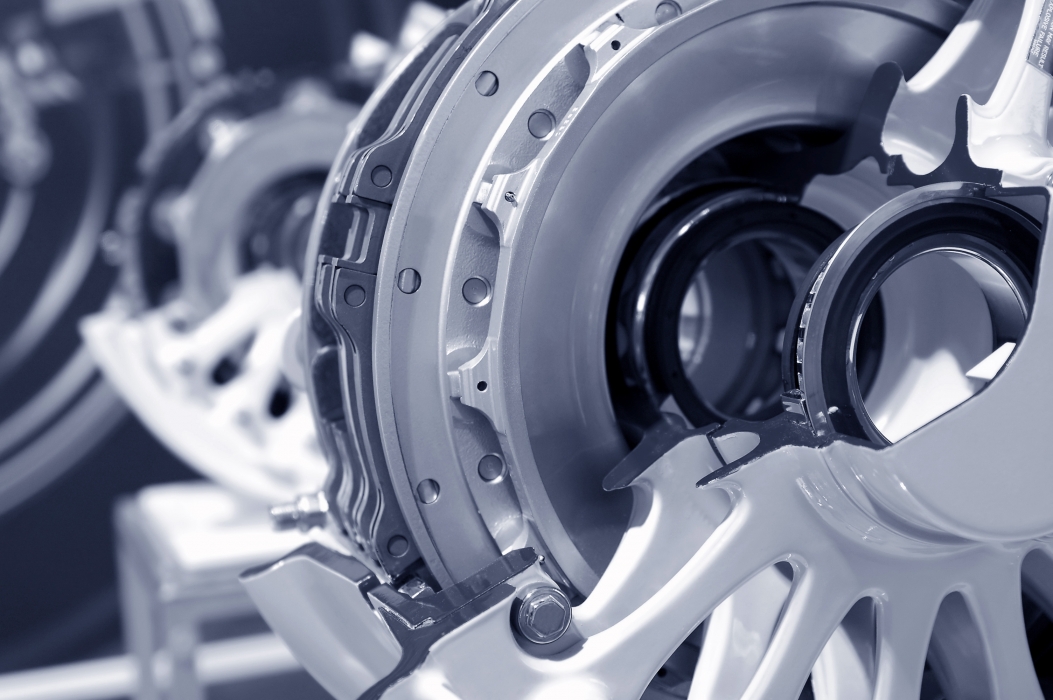

From a simple spindle to sophisticated assemblies such as blisks and fir trees, wet blasting (otherwise known as vapor blasting) is capable of processing aerospace components of varying shapes and sizes. It is also well suited for the finishing of a range of materials including any metal as well as composites and additive manufactured components.

With automation and high specification capabilities, wet blasting can be applied to a range of surface finishing applications for the aerospace industry including:

- Cleaning prior to inspection for cracks or non-destructive testing (NDT)

- Titanium scale removal

- Surface preparation for coating, bonding or painting

- Paint stripping without substrate damage

- Surface preparation for composite bonding

- Removal of conformal and abradable coatings

- Post-process finishing for additive manufactured components

- Degreasing, de-rusting and descaling of parts

- And, even aircraft toilet cleaning

Along with high levels of process control, wet blasting can ensure reliable, high-quality surface finishing of jet engine turbine blades, wheels and other components every time – crucial when the performance of every component is important!

Want to learn more about how wet blasting works and its benefits for aerospace? Click the link below to be taken to our dedicated aerospace industry page.