Benefits

- Increased aesthetics with uniform finishes

- Reduced processing with combined cleaning and decaling

- Improved life with edge preparation

- Stronger coatings with improved surface preparation

- Tougher blades through peening action

In the manufacture of bi-metal and carbon steel band saw blades there will be a requirement for surface finishing or treatment of the blades during production. Wet blasting is a mechanical surface treatment technology that offers consistent and repeatable processing for a number of applications.

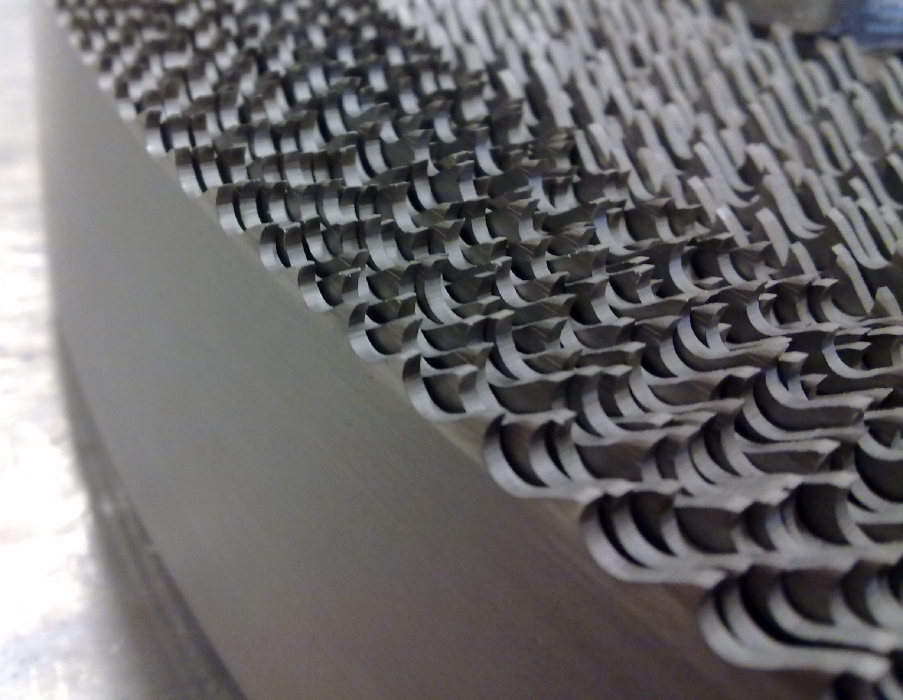

The Vapormatt wet blast process has been used by band saw blade manufacturers to remove scale after heat treatment or welding, to peen blades after machining or punching, to provide a homogenous cutting edge to improve tool life and also to prepare blades for coating by offering a very clean, very reactive surface.

Using an in-line wet blasting machine with band saw blade gantry blast nozzles can be positioned around the blade to deliver the blast to achieve uniformity when it comes to cleaning and descaling as well as adjusting the angles to provide edge honing and peening. The controls behind the wet blast process means that each blade is process with a high level of consistency and at line speeds of up to 10m/min.

A range of blast medias can be used from glass to beads to ceramics and alumina to silicon carbide which will be specified depending on the required application. Additionally the air and slurry pressures can be adjusted to change the processing environment from harsh to soft depending on the blade type and required finish.

To date Vapormatt have worked with a number of large band saw blade manufacturers across the globe. The introduction of wet blasting and the Vapormatt Profelis machine has enabled these manufacturers to add value to their products through improved life and higher quality finishes.

If you have a band saw blade surface preparation requirement we have a team of wet blasting application specialist available to help.

You can visit the download section for more literature, call us on +44 1823 257 976 or send us an email.