We’ve just finished our Factory Acceptance Test (FAT) on a large automatic Leopard Horizontal wet blasting machine destined for a leading aerospace MRO operation in the Middle East.

This machine is capable or processing all sorts of large aerospace components (e.g. large wheels, fan blades, fan discs, etc.) for MRO related applications like preparation for NDT crack detection.

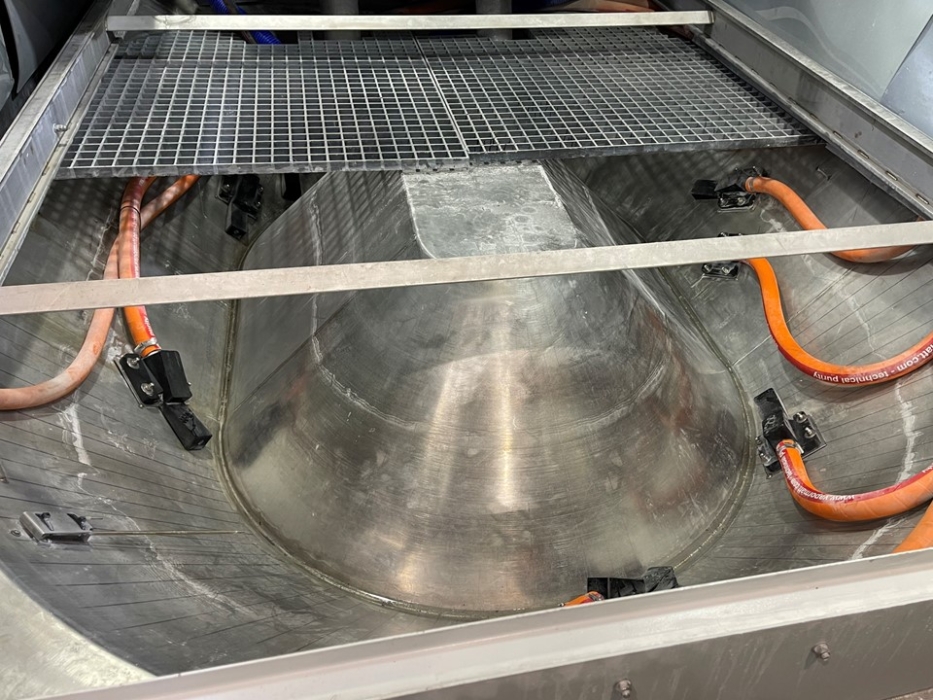

The sump on a machine this size is inevitably large. To keep the working height of the machine to a level that allows easy loading and unloading of components, a pit would normally have to be dug in the factory floor to accommodate the machine’s sump.

To avoid the considerable inconvenience and expensive associated with digging a bit, our R&D dept. invented and patented the ‘Doughnut Sump.’ Water and abrasive is thoroughly mixed together as it travels around the sump prior to being pumped to the blast guns.

The sump’s innovative design is another example of why leading manufacturers, and in this case leading aerospace MRO operations, look to our unrivalled wet blasting technology for their surface finishing needs.

Keep an eye on our LinkedIn page for the video of this machine in operation.