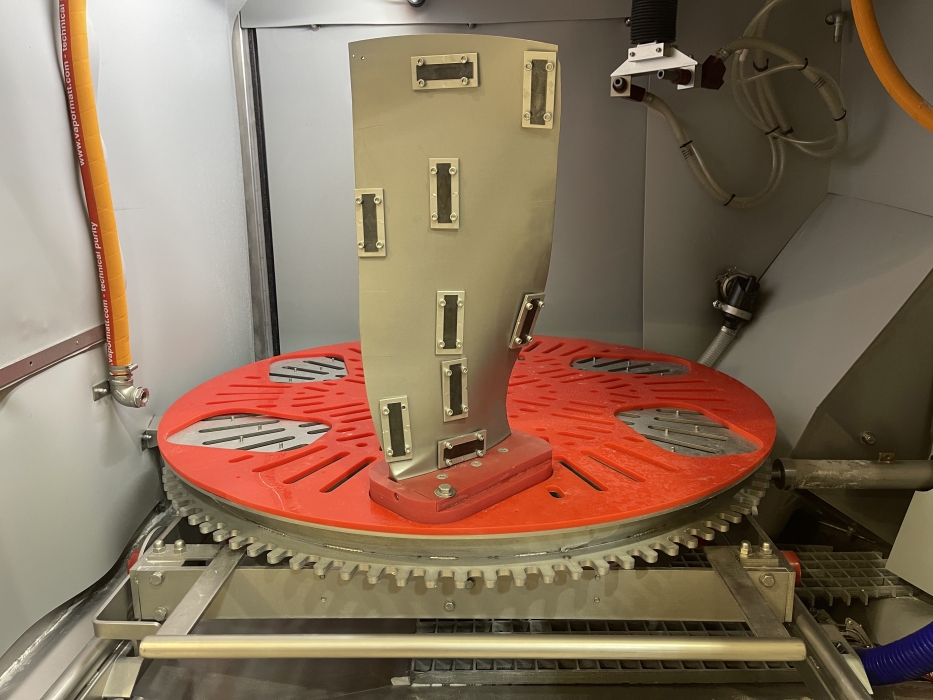

In aerospace, surface integrity defines fatigue life, reliability, and cost. For turbine and fan blades, wet shot peening by wet blasting has become the proven way to deliver stronger components and more predictable outcomes for both OEM and MRO operations.

Here's why wet shot peening is increasingly preferred to dry shot peening:

• Substantially longer component life - Wet shot peening introduces controlled compressive stresses into the blade surface. This refines the grain structure and reduces crack initiation, delivering dramatic improvements in fatigue strength. In service, turbine blade life extensions of more than 1000 percent have been recorded.

• Same peening intensity, greater surface protection - Wet peening achieves equivalent intensity to dry shot peening, but with the cushioning effect of water. This protects thin sections and complex aerofoil geometries, reducing the risk of surface damage on critical components.

• Consistent, high-quality finishes - The flow of water and media produces smoother, more uniform finishes across intricate blade profiles. This level of consistency is difficult to achieve with dry systems, particularly on irregular shapes.

• Reduced contamination risk - Wet shot peening uses ceramic or stainless steel media as standard. This removes the risk of non-ferrous contamination and supports tighter aerospace quality requirements.

• Precise process control - Modern wet blasting systems provide exceptional control through integrated HMIs, live monitoring, and automatic parameter adjustment. For aerospace MROs, this repeatability is critical to meeting specification and audit requirements.

• Lower operating costs - Water cushions the media, reducing breakdown and allowing effective recycling through filtration. Both media and water remain in the system longer, significantly reducing consumable spend.

• Cleaner and safer operations - Wet shot peening is dust-free by design. This simplifies post-process cleaning, improves operator health and safety, and removes the need for costly ATEX dust extraction when processing materials such as titanium alloys.

• No pre-cleaning step - Components can enter the process with oil or grease present. These contaminants are removed during peening and filtered out automatically, reducing handling time and improving throughput.

For OEMs, wet shot peening builds durability into new engine components.

For MROs, it delivers longer life, repeatable quality, and a safer, more efficient shop floor.

If surface engineering plays a critical role in your engine performance strategy, it may be time to reassess whether dry shot peening still meets today’s demands.