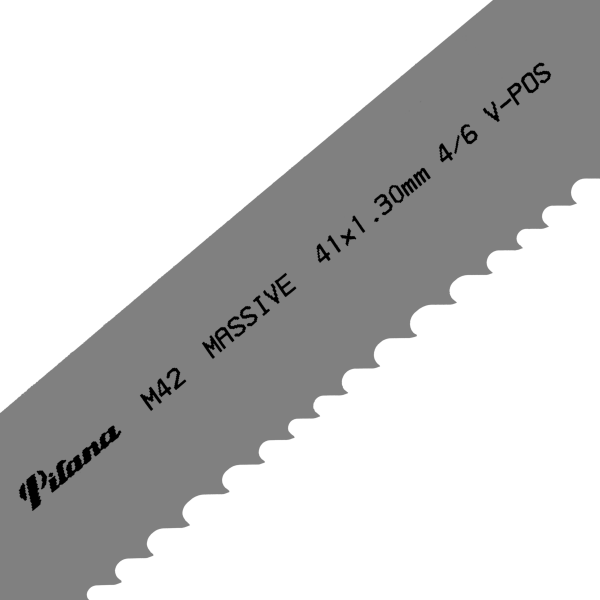

In the manufacture of bandsaw blades, surface preparation is a critical step when it comes to applying durable and legible branding. Wet blasting offers distinct advantages over conventional finishing techniques for this purpose.

• Uniform surface profile: Wet blasting creates a controlled, consistent surface roughness that improves the absorption and adhesion of subsequent branding processes such as laser marking, etching or stamping.

• Oxide and contamination removal: The process efficiently removes mill scale, heat treatment residues and surface contaminants, providing a clean substrate that ensures high-contrast marks.

• Improved mark longevity: A well-prepared surface enhances the permanence of logos, serial numbers and technical identifiers, ensuring traceability throughout the blade’s service life.

• Surface reflectivity control: Wet blasting can be tuned to reduce glare or shine, which improves the readability of laser marks under different lighting conditions.

• Enhanced corrosion resistance: By cleaning and texturing the surface, wet blasting can help subsequent protective coatings or passivation treatments adhere more effectively, ensuring branding remains visible even in harsh environments.

• Precision finishing: The process allows for very fine control over the surface profile, so you can tailor finishes specifically for different marking technologies (e.g. deeper texture for stamping, smoother finish for high-resolution laser marking).

• Reduced post-processing: The finish achieved with wet blasting often eliminates the need for secondary polishing or cleaning steps before branding, saving time and reducing variability.

For manufacturers, the result is greater consistency in branding, improved process reliability and the ability to meet increasingly stringent traceability requirements.

Learn more about the applications and advantages of wet blasting for bandsaw blade manufacturers