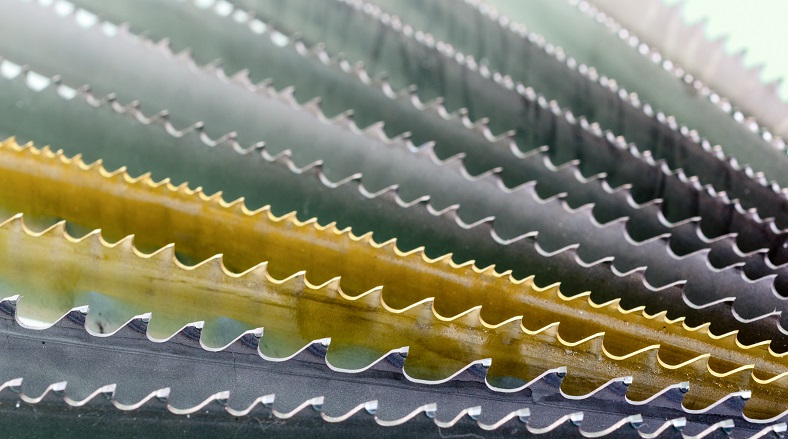

Few people think about what gives a bandsaw blade its incredible strength and durability. Behind every precise cut is a science of surface engineering - and one of the most effective yet underrated techniques is wet blasting.

For bimetal bandsaw blades, wet blasting does far more than just clean. It refines, strengthens and prepares every surface for peak performance - and impressively, both peening and surface finishing can be achieved in the same wet blast operation, making it ideal for efficient, high-quality production.

Here’s what wet blasting can do:

• Cleaning and descaling: Removes oxides and residues after heat treatment and welding, ensuring a flawless foundation.

• Deburring: Eliminates small burrs and sharp edges created during machining, improving blade consistency and reducing stress concentrations.

• Preparation for coating: Produces a uniform, activated surface that enhances adhesion for anti-wear, anti-corrosion and friction-reducing coatings, including paints and oils, ensuring both performance and longevity.

• Peening and surface finishing combined: The slurry process induces beneficial compressive stresses while simultaneously polishing the surface - delivering strength and the perfect surface in one precise step.

The results speak for themselves: stronger blades, smoother cuts, improved coating performance, and a cleaner, more sustainable process overall.

Learn more about the applications and advantages of wet blasting for bandsaw blades