The increasing performance demands on machine tools and rising market competition has driven a need for a greater understanding of the manufacturing processes. To produce a high quality and successful cutting tool four elements must be considered. Until recently most consideration has been given to the substrate, geometry and coating processes with a large understanding and several established technologies available. The fourth element, edge preparation, has only recently attracted a wider interest. To ensure a stable performance of the cutting tool it is important to achieve a homogeneous rounding along the major and minor cutting edge and corners. With a range of techniques emerging for edge preparation this is still regarded as one of the more “mysterious” stages of production and has led to much research and development to achieve greater accuracy and control in edge preparation. This white paper looks to explain the need for edge preparation and to evaluate the benefits of the micro-wet blasting process; presenting it as one of the more controllable processes available.

Figure 1. The four elements that define tool performance

Why edge preparation is needed

Edge preparation is the process of rounding or radiusing the cutting edge of a tool. In radiusing a cutting edge to form a bigger area the likelihood of the tool chipping is reduced and coating adhesion increased, with the combination of these factors ultimately leading to a longer tool life. Through radiusing the cutting edge it has a more stable form that can offer increased performance by up to 500% (Influence of Edge Preparation on the Performance of Coated Cutting Tools. Platit (2007). International Conference on Metallurgical Coatings and Thin Films.). There is also a need to improve the surface finish of the tools through cleaning as this will provide a better substrate on which to coat. Using edge preparation processes to improve surface Ra coated tools will be more uniform, allowing for more homogenous wear that, again, increases the stability of the cut and reduces the risk of chipping and flaking.Without edge preparation, the efficiency of the manufacturing operation is reduced by increased downtime and higher rates of waste as tools must be replaced more frequently. With sharper “unprepared” tools manufacturers may see quicker cuts but without any edge preparation the stress concentration at the edge is found to be a large cause of chipping [1]. Similarly, a sharper cutting edge makes for poor heat dissipation and, with temperatures reaching upwards of 1000 deg c, can be another cause of tool failure. Studies have shown that a radiused tool will allow heat to spread throughout the tool, reducing stresses [2]. However, given the range of tool substrates, cutting applications and types of tools there is no “one size fits all” approach to edge preparation making the controllability of this process an important requirement for anybody looking to improve tool life as different tools will need different radii.

The benefits of Wet Blasting

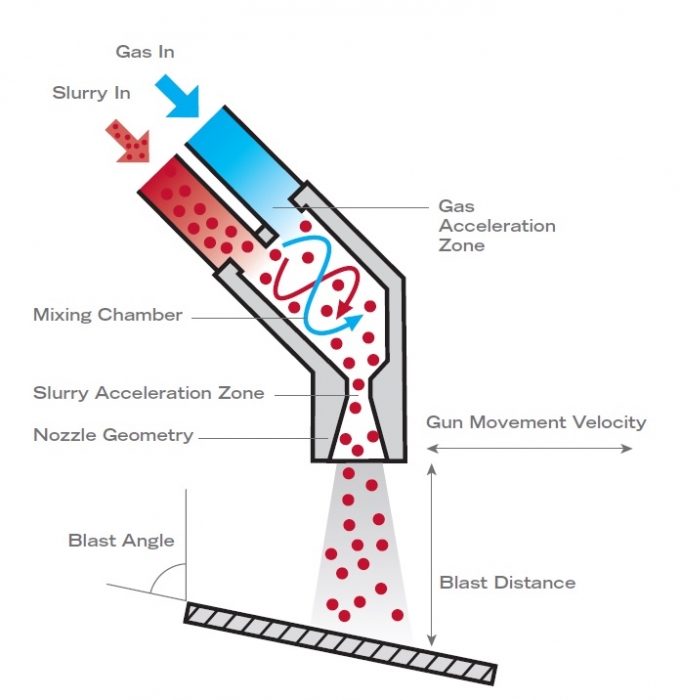

The use of micro blasting for edge preparation has been around for a long time with it having been proven to be one of the more effective methods for edge preparation [3]. The ability to offer controlled edge radiusing to within +/-5 micron (up to 100 microns) tolerance of specification coupled with HF1 surfaces makes the micro wet process a preferred solution for many manufacturers. The wet process combines compressed air, abrasive media and water in a slurry form to create a mechanical action that gives an abrasive effect.

Figure 2. Cross section of the wet blast gun.

By using wet blasting to remove and round the top layers of the surface the process can be used to reduce high peaks found after grinding or sintering. In reducing the surface roughness and removing particles of cobalt there is a lower mean between peaks, which has the benefit of improving coating adhesion. [4]

Wet blasting also offers a much more consistent finish with the lubricating effect of the water creating a flow of slurry that ensures an even and uniform surface. This is unlike other micro-blasting processes where a heavier impact and lack of flow create unpredictable results with an increased chance of chipping and uncontrollable wear.

The use of water creates a lubricating effect, which increases the flow of particles across the surface being treated. Unlike dry blasting, the liquid cushion also protects delicate surfaces that prevents media particles being left in the substrate. Consequentially, wet blasting results in surfaces that are clean to a HF1 level. To further improve this the water can be heated with mild detergent and antioxidants added to ensure an even more thorough action that will reduce the risk of cobalt leaching.

Controlled wet micro blasting can also offer great benefit post coating. With the correct media selection wet micro blasting systems can offer a peening action. Given the nature of the coating process, and the temperatures involved, several tensile stresses can be eliminated and replaced by compressive stresses distributed evenly across the coating and substrate. A peened coating can make flaking or adhesion failure less likely whilst also offering a polishing effect to remove droplets found after CVD coating.

The most advanced wet micro blasting systems use powerful software programs to control and monitor precise flows of liquid, gas and solids, which are mixed then accelerated through focused blasting nozzles. Changing the air and slurry pressures, blast media, slurry concentration, number and angle of attack and distance of the blasting nozzles allows for a range of processing effects to be achieved which can be utilised to give a range of cutting forms including waterfall and trumpet hones. Additionally, media concentration, process temperature, additive and blast pressures can be carefully controlled to provide an extremely consistent surface finish that can be reproduced time after time.

The leading systems for wet micro blasting currently control up to 15 variables which allows users to increase the predictability of tool performance. The extent of their controllability is pushing boundaries in terms of edge preparation as it becomes easier to achieve and therefore experiment with new and different edge hones and forms.

Innovations in edge honing for wet blasting

With such benefits to be gained it is hardly surprising that designers and engineers are continuing to refine the process with new innovations, allowing tool manufacturers to take greater control of their edge preparation processes. The most recent example of innovation is the Vapormatt Sabre. The unique nozzle arrangements of the Sabre allow hybrid functionality with the same controllability and consistency of results as larger, more complex, systems. The Vapormatt Sabre has been developed in response to customer demand to serve three new user groups, offering small to medium volume manufacturers, coating centres and R&D facilities a cost-effective, high performance wet blasting system with the controllability to significantly enhance output quality on a range of cutting tools.

Vapormatt manufactures a wide range of equipment suitable for cutting edge preparation and face processing of all HSS and carbide tooling including rotary shank tools (drills, taps, mills etc.) indexable inserts, hobs and saws. It also offers a custom engineering service (known as Wet Blast Support Services) to help businesses to incorporate wet blasting process technology into existing equipment or into in-house designs for critical process machinery.

In summary, wet blasting offers exceptionally high quality results that are increasingly being recognised globally by many tool manufacturers. And with the ability to offer controlled and repeatable results wet blasting not only improves tool quality and life but is also kinder to the environment with less consumables needed and no harmful chemicals. In recent years we have seen a stabilisation of global machine tool output, recovering from the global recession that hit the industry hard in 2009 when almost a 1/3 of the total output was wiped out. It is now time for the industry to work harder and smarter to extend tooling life expectancy.

About Vapormatt

The global Vapormatt Group was established in 1978 and the Head Office is based in Taunton, Somerset in the UK. The Company is owned by the third generation of the Ashworth family. As the originators of the pressure recirculatory wet blast process, the Ashworth family have accumulated experience and expertise in this field for over 50 years. The Company designs and manufactures manual and automatic surface cleaning, peening and finishing machines, using the Vapormatt Wet Blast and High Pressure Water Systems.

[1] Cutting edge preparation of precision cutting tools by micro-abrasive jet machining and brushing. Kassel University (2009). Carlos Julio Cortes Rodriguez – Dissertation.[2] Kim, K.; Lee, W.; Sin, H: A finite-element analysis of machining with the tool edge considered. In: Journal of materials processing technology86 (1999), S. 45-55). [3] H.K.Tonshoff, C.Blawit, Influence of surface integrity on performance of coated cutting tools, Thin Solid Films, 308-309 (1997), 345-350. [4] K.D.Bouzakis, N.Michailidis, G.Skordaris, S.Kombogianis, S.Hadjiyiannis, K.Efstathiou, G.Erkens, S.Rambadt, I.Wirth, Effect of the cutting edge radius and its manufacturing procedure, on the milling performance of PVD coated cemented carbide inserts, Annals of the CIRP, vol. 51/1 (2002), pp. 61-64.