Endosteal

• Typical substrate: CNC-machined titanium rod / bar (commercially pure or Ti alloy); less commonly zirconia from a ceramic block

• Finishing issue: CNC tool marks + micro-burrs; coolant/oils; possible retained grit/residues after blasting

• Wet blast: Final clean + gentle deburr + uniform matte/microtexture; good flushing of threads / undercuts.

Subperiosteal

• Typical substrate: Additively manufactured (powder-bed fusion) titanium, sometimes with machined interface features

• Finishing issue: Trapped powder/partially fused particles; high as-printed roughness; support scars; hard-to-reach crevices

• Wet blast: Excellent for depowdering/cleaning complex geometry; helps level to a more uniform finish.

Transosteal

• Typical substrate: CNC-machined plate/screw components; often titanium alloy in classic “staple” designs (some variants reported in other alloys)

• Finishing issue: Sharp edges / burrs; crevices trap residues

• Wet blast: Edge conditioning and cleaning without dry-blast dust; useful for flushing crevices.

Zygomatic

• Typical substrate: CNC-machined extra-long titanium implant blank (commercially pure Ti or Ti alloy)

• Finishing issue: Long threads increase residue retention risk; consistency over full length

• Wet blast: Thorough cleaning / flushing and consistent conditioned finish along long threads.

Pterygoid

• Typical substrate: CNC-machined long / angled titanium implant blank (commercially pure Ti or Ti alloy)

• Finishing issue: Long/angled geometry complicates cleaning; micro-burrs can persist

• Wet blast: Controlled deburr and cleaning in complex thread forms / recesses.

Narrow-diameter / “Mini”

• Typical substrate: CNC-machined titanium alloy rod/bar stock

• Finishing issue: Sensitive to over-finishing (feature rounding/thread damage); needs gentle, repeatable finishing

• Wet blast: Process-controlled cleaning / deburr with a controlled matte finish.

Short implants

• Typical substrate: CNC-machined titanium rod/bar (commercially pure Ti or Ti alloy)

• Finishing issue: Less surface area means tighter control of final surface state; dense threads can retain residues

• Wet blast: Consistent cleaning / conditioning, especially for dense threads.

One-piece

• Typical substrate: CNC-machined titanium from rod / bar, or zirconia milled/ground from a ceramic blank

• Finishing issue: Harder to zone-finish; plaque-facing zones usually need smoother finish than bone-facing

• Wet blast: Selective finishing / cleaning with masking / controls to manage zones.

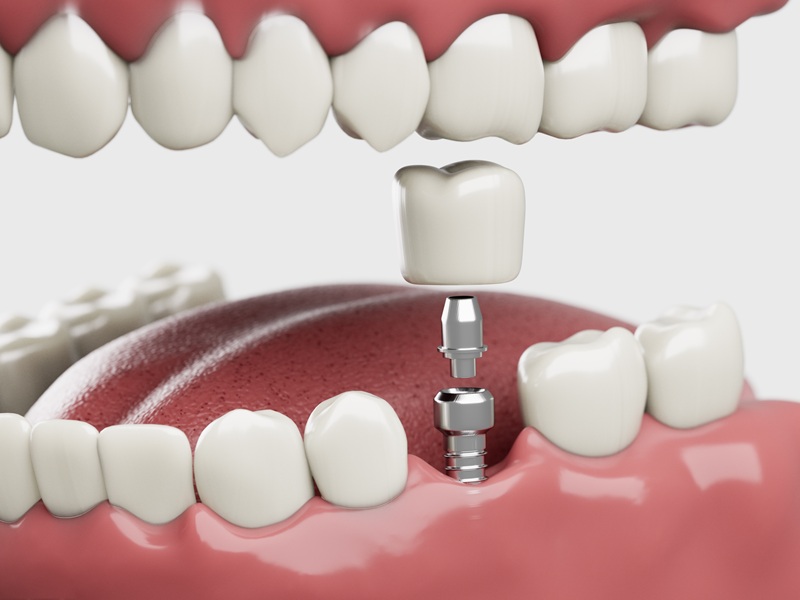

Two-piece

• Typical substrate: CNC-machined titanium implant body + CNC-machined titanium / Ti-alloy abutment blank

• Finishing issue: Protect precision connection surfaces; retained residues / contamination and tolerance change risks

• Wet blast: Mask precision interfaces; clean / condition implant body reliably.