Spallation is cracking, flaking, or delamination of a coating from the surface of a part.

In AM components, it often leads to coating failure under stress, heat, or corrosion.

Why does spallation happen?

• Surface contamination (residual powder, oxides)

• Poor surface roughness control

• High residual stresses

• Weak mechanical bonding

How does wet blasting help?

• Deep cleaning: Removes powders, oxides and oils — no residue left behind.

• Ideal surface roughness: Creates a consistent texture for better coating grip.

• Surface activation: Boosts surface energy for better wetting, stronger bonding.

• Stress reduction: Gentler than dry blasting, no microcracking, lower delamination risk.

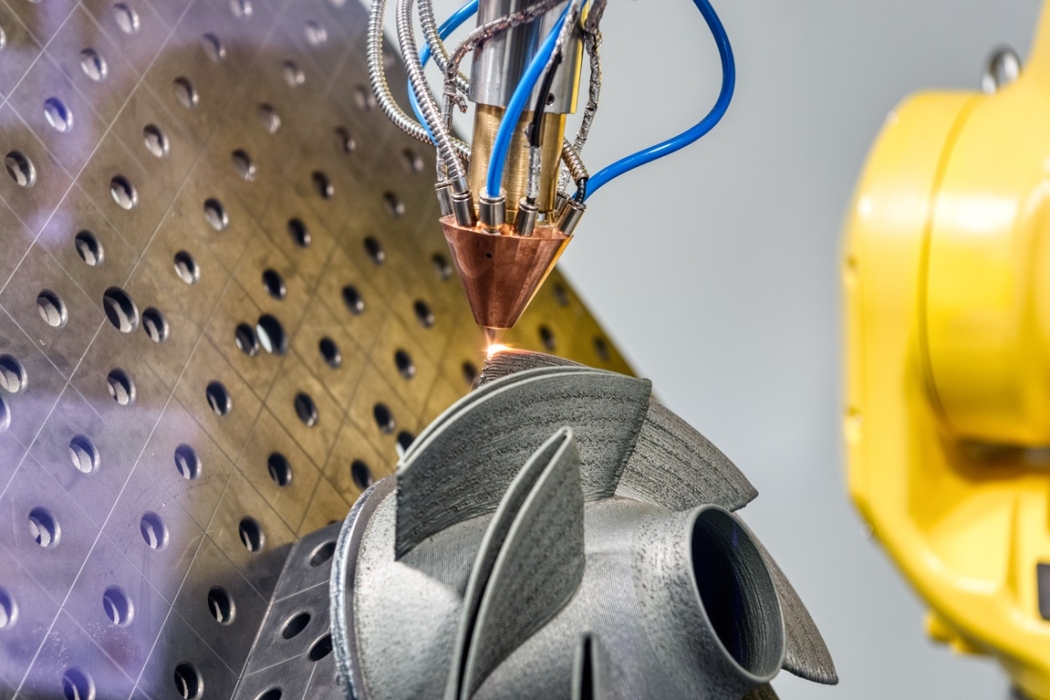

• Geometry friendly: Cleans complex internal channels and fine features without damage.

Results

✅ Stronger adhesion

✅ Longer lasting coatings

✅ Lower failure rates in service

Ideal for high-stakes industries: aerospace, energy, medical, defense