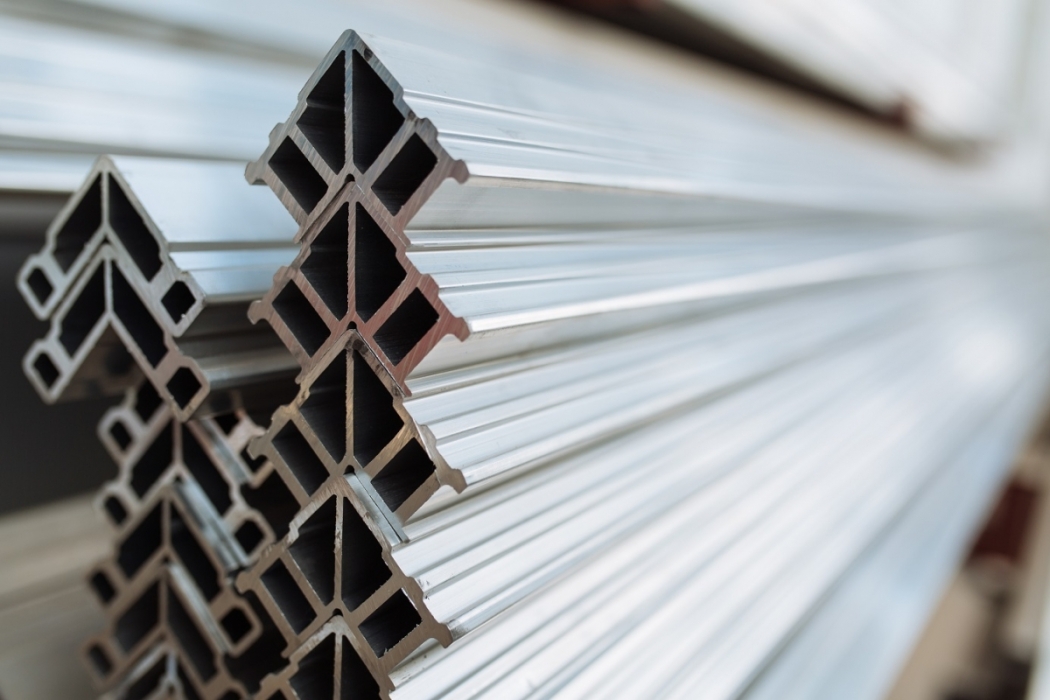

In the fast-paced world of aluminium extrusion, precision and consistency are everything. For award-winning New Zealand manufacturer Altus, keeping extrusion dies perfectly clean between production runs isn’t just maintenance - it’s mission-critical to ensuring the flawless finish their customers expect.

With a wide product range and demanding production schedule, Altus needed a way to clean dies quickly, thoroughly, and safely without altering their geometry. Their solution? The Vapormatt Cougar wet blasting machine.

Here’s what made the difference:

• Speed and reliability – The Cougar removes all caustic traces and aluminium residues efficiently after caustic soda dipping.

• Precision cleaning – The cushioning effect of water protects die profiles while polishing critical bearing surfaces.

• Quality inspection made easy – With perfectly cleaned dies, imperfections can be identified and corrected faster.

As Jacques Naudé, Process Improvement Engineer at Altus, put it:

“The machine works well and does a great job at cleaning dies.”

It’s a simple statement that says a lot - about trust in technology, attention to detail, and a culture of continuous improvement.

Learn more about the applications and advantages of wet blasting for aluminium extrusion dies