In high-performance sectors such as aerospace, motorsport and advanced manufacturing, reliable adhesive bonding on composite parts is essential.

Surface preparation plays a far bigger role than many realise.

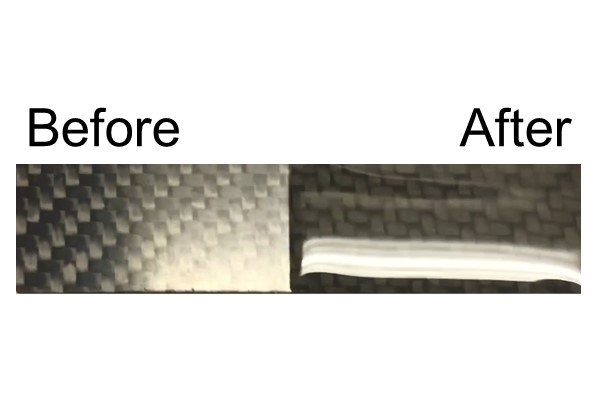

Here’s why wet blasting is the best finishing process for preparing composite surfaces prior to bonding:

• Creates an ideal wet-out surface for adhesives - Wet blasting produces a hydrophilic surface, allowing adhesives to spread evenly rather than bead up. This improves coverage and contact, which are critical for bond integrity.

• Effectively removes surface contaminants - Residual mould release agents, grease and handling contamination are removed without embedding debris into the surface, leaving it thoroughly clean and bond-ready.

• Improves bond strength and consistency - The process creates a controlled micro-texture and increases surface energy, helping adhesives achieve stronger and more repeatable bond performance.

• Protects fibres and resin systems - The presence of water cushions the abrasive impact and prevents excessive heat build-up, reducing the risk of fibre damage that can occur with dry blasting or aggressive sanding.

• Delivers repeatable results on complex geometries - Wet blasting can be tightly controlled and automated, making it well suited to intricate composite components where consistency matters.

For organisations working with bonded composite assemblies, wet blasting offers a reliable way to improve joint performance without compromising material integrity.