In aerospace MRO, every decision impacts cost, precision, and shop efficiency. One shift gaining traction is moving from dry blasting to wet blasting — and for good reason.

Here’s why wet blasting is increasingly preferred for wheel and brake maintenance:

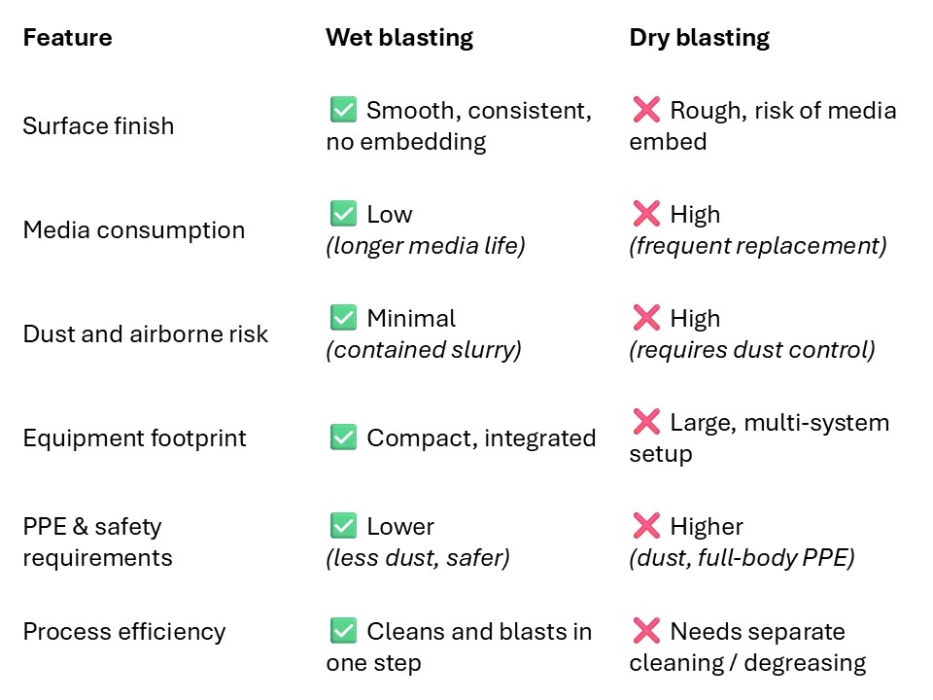

✅ Superior surface finish: Wet blasting delivers consistent, contaminant free surfaces — critical for aluminium and magnesium components. No media embedment. No reworking headaches.

✅ Lower operating costs: Reduced media consumption, less rework, and minimal PPE requirements add up to real savings.

✅ Cleaner, safer work environment: The water-based blast media slurry keeps dust and debris contained, making for safer conditions and less reliance on large filtration systems.

✅ More space efficient: Wet blasting combines cleaning and blasting in one compact unit — freeing up valuable shop floor space.

✅ OEM-aligned: Many aerospace OEMs now recommend wet blasting for wheels, brakes, and landing gear due to its unparalleled control and reliability.