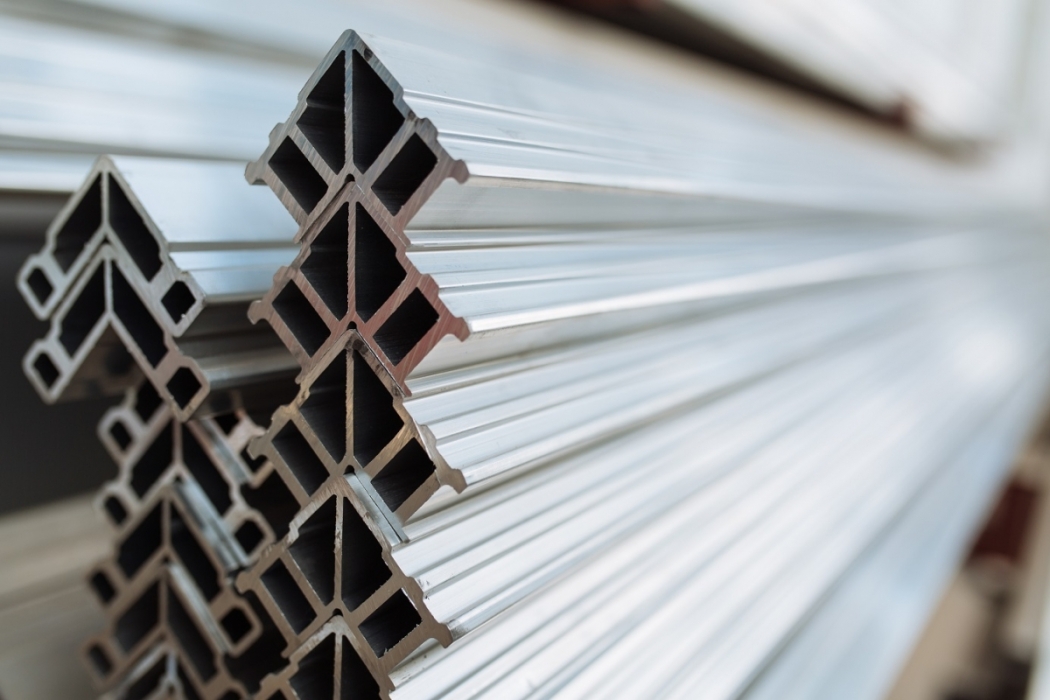

When maintaining aluminium extrusion dies with intricate internal geometries — deep ports, bearings, and complex channels — cleaning isn’t just about removing build-up; it’s about preserving precision and die life.

Among available methods, wet blasting consistently outperforms dry blasting, chemical cleaning, and ultrasonic systems.

Here’s why:

- Superior reach into tight, tortuous features via the fluid water / abrasive slurry

- Gentle, controlled cleaning that maintains critical tolerances and edge geometries

- Excellent thermal management, avoiding distortion in thin-walled areas

- Consistent, thorough contaminant removal, minimising time required in the caustic soda dip or even its concentration

For extrusion operations where die integrity drives product quality and process efficiency, wet blasting isn’t just preferred — it’s essential.