Sustainability is no longer just a focus for consumer industries. It’s fast becoming a priority across the defence sector too. As environmental regulations tighten and expectations continue to rise, defence manufacturers are realising that eco-friendly practices are not a compromise on performance but a genuine strategic advantage.

From cutting hazardous waste to improving workplace safety, greener manufacturing and maintenance helps meet compliance standards, strengthens reputation, and supports long-term efficiency.

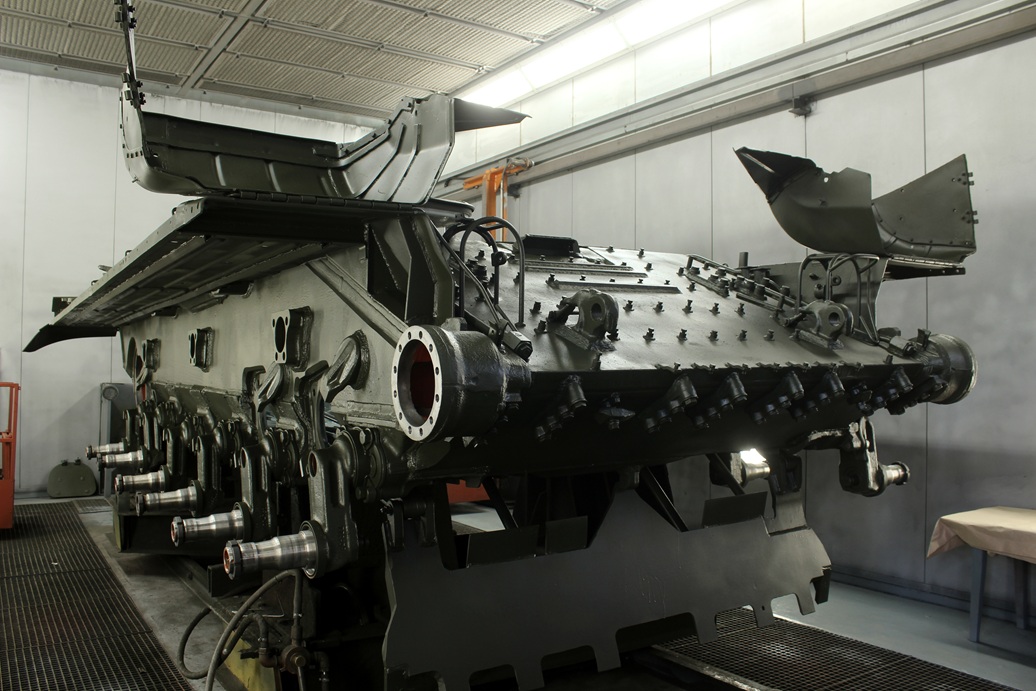

One process driving this change is wet-blasting, also known as vapour blasting. Unlike traditional dry blasting, wet-blasting uses a mixture of water and abrasive media to create a cleaner, safer, and more sustainable surface preparation method.

• Reduces dust and airborne contaminants to improve air quality and operator safety

• Extends media life, reducing waste and disposal costs

• Minimises chemical use, removing the need for harsh cleaners and solvents

• Protects precision components, reducing material waste and rework

By adopting technologies such as wet-blasting, defence manufacturers can maintain the highest quality standards while advancing sustainability and environmental responsibility.

Eco-friendly innovation is not only good for the planet; it’s good for business and for the future of defence manufacturing.

Learn more about the applications and advantages of wet blasting for defence