Control and automation

With our core focus on process control, our wet blasting machines lead the way when it comes to repeatable and reliable processing.

| Uniform surface | Repeatability | Environmental | Precision | Peening | Cutting tool Edge Honing | De burring | Reactive Surface | Oily / Wet contamination removal | Corrosion Removal | Concurrent application of corrosion inhibitor | Capital cost | Running cost | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Wet Blasting

|

Good

|

Excellent

|

Good

|

Excellent

|

Good

|

Excellent

|

Good

|

Excellent

|

Excellent

|

Excellent

|

Excellent

|

$$$

|

$

|

|

Dry Blasting

|

Good

|

Good

|

Poor

|

Excellent

|

Good

|

N/A

|

Average

|

Poor

|

N/A

|

Excellent

|

N/A

|

$$

|

$$

|

|

Shot Blasting

|

Good

|

Good

|

Poor

|

Excellent

|

Good

|

Excellent

|

Good

|

Poor

|

N/A

|

Good

|

N/A

|

$$

|

$$

|

|

Shot peening

|

Average

|

Good

|

Poor

|

Excellent

|

Excellent

|

N/A

|

Average

|

Poor

|

N/A

|

Average

|

N/A

|

$$$

|

$$

|

|

Chemical Cleaning

|

Good

|

Excellent

|

Very poor

|

Poor

|

N/A

|

N/A

|

Poor

|

Good

|

Good

|

Good

|

Good

|

$$$

|

$$$

|

|

Vibro Finishing

|

Average

|

Excellent

|

Good

|

poor

|

N/A

|

N/A

|

Excellent

|

Good

|

Poor

|

Excellent

|

Excellent

|

$

|

$

|

|

Brushing

|

Poor

|

Poor

|

Excellent

|

poor

|

N/A

|

Good

|

Average

|

Poor

|

Good

|

poor

|

good

|

$

|

$

|

|

HP Washing

|

Good

|

Poor

|

Poor

|

Average

|

Poor

|

N/A

|

N/A

|

Poor

|

Poor

|

Good

|

Poor

|

$

|

$

|

Flawless finishing where consistency is key

The ability to work with additives, such as degreasing agents or inhibitors, can improve the usefulness of wet blasting machines by combining process steps. The water eliminates the heat that can damage delicate surfaces, any static build up and the embedment of blast media in soft surfaces. It also increases the media flow over the work pieces, which improves the uniformity of the process to give more homogenous finishes. The improved finishes are critical in industries were consistency is key for the manufacturing process and downstream applications such as bonding or coating.

Processes to suit your products

Wet blasting changes the surface profile and can, for example, produce a highly clean and reactive surface for coating. It can also remove burrs, machining notches, heat marks and heat scale. Other processes include the strengthening and hardening of surfaces by reducing tensile stresses and accurately honing cutting tool edges, allowing bandsaw blades to run at full speed from new and lengthening their life for example. Unlike dry-blasting, very fine abrasives can be used for those processes that require extra precision. All processes are carried out whilst simultaneously cleaning and degreasing.

A cleaner way to work

Adding water to the process contains and controls the abrasive, meaning the workspace is cleaner and safer, lowering the time and money needed for cleaning due to a lack of dust. Unlike dry-blasting, certain applications can be done in-line, in a contained environment, helping to save space and improve productivity. The lack of dust also prevents re-contamination, a particular benefit for electrical components, and eliminates the risk of dust explosion.

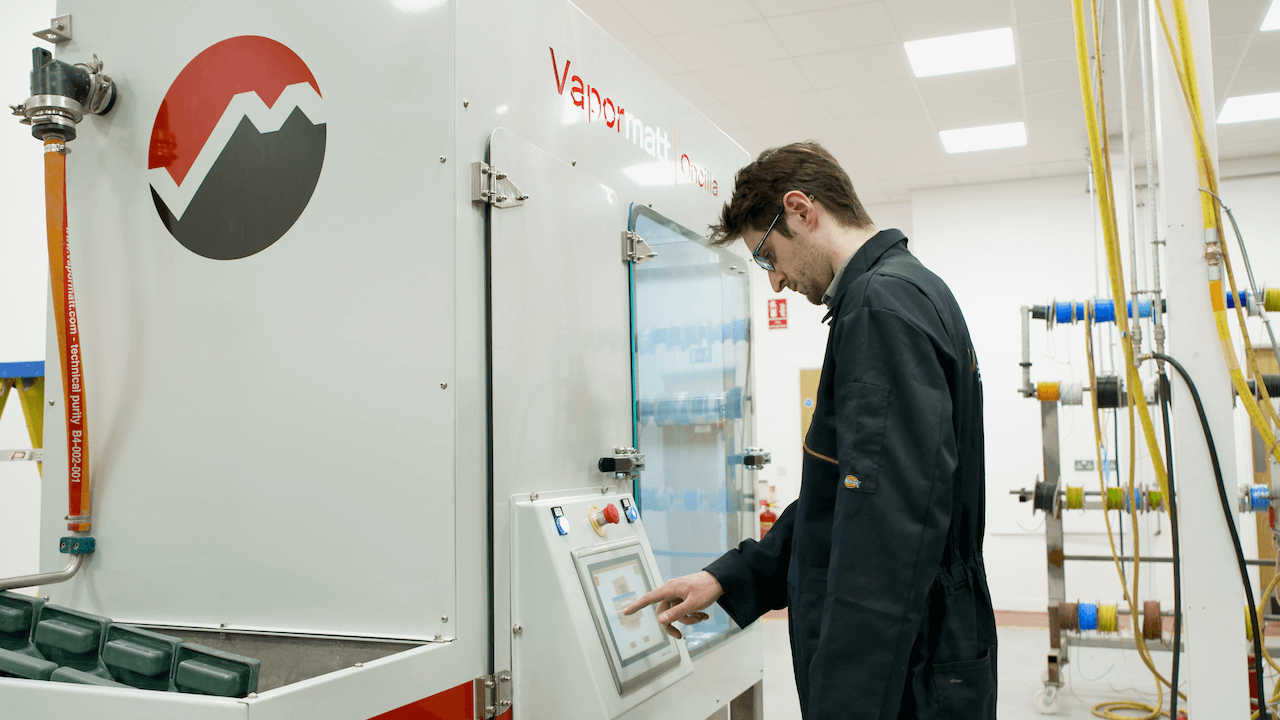

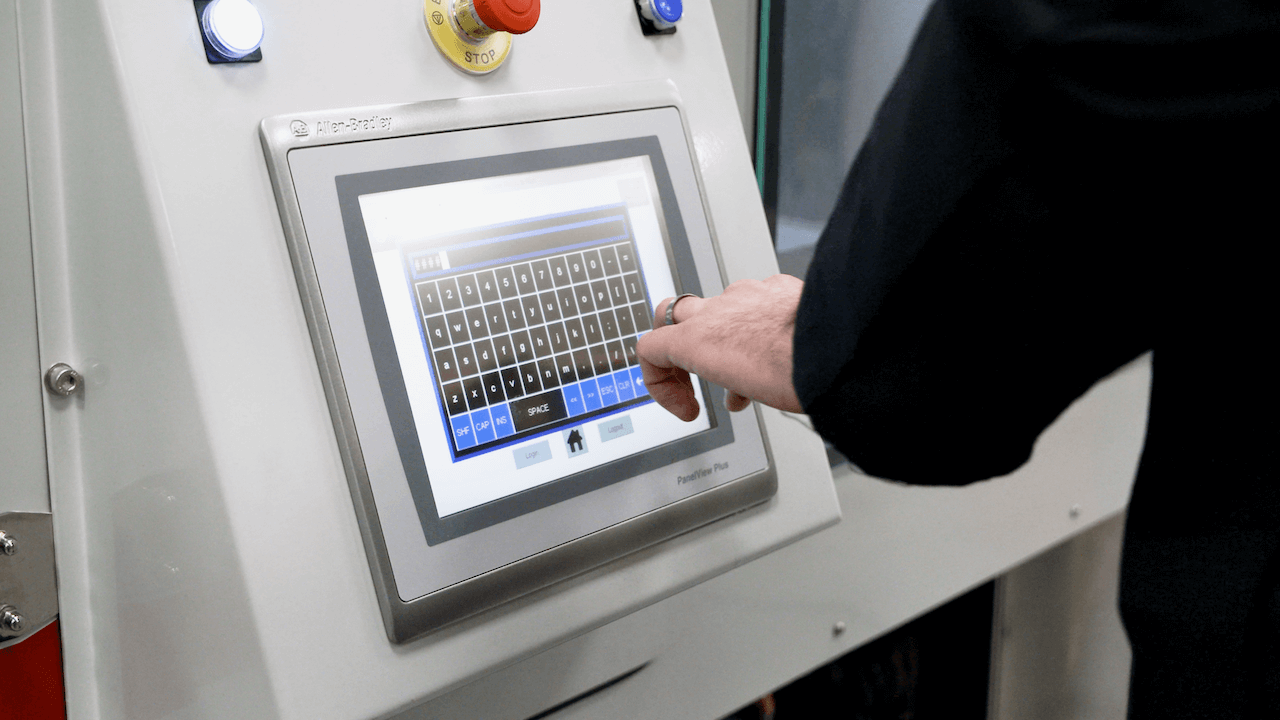

Control and repeat… and repeat…

With many industries increasing the requirements for quality and process monitoring, wet blasting offers in-depth control to its users. With the most controllable parameters for any mechanical surface treatment, it becomes possible to measure and control almost every variable in the process. With Vapormatt wet blasting machines, users can create optimum conditions that are then maintained, improving the reliability of the process and increasing the quality of the products being treated.

Better for your bottom line

By adding water to the process, it gives users more control of the abrasive impact on the work pieces. Adjusting both water and air pressure can also reduce the abrasive media consumption, and by having the abrasive cushioned in water, it increases the life of critical wear items such as hoses and nozzles. And, because everything is controlled, you can automate and work in line. Lowering costs for replacement parts and increasing productivity.

Perfect for your planet

The ability to work with additives, such as degreasing agents or inhibitors, can improve the usefulness of wet blasting machines by combining process steps. The water eliminates the heat that can damage delicate surfaces, any static build up and the embedment of blast media in soft surfaces. It also increases the media flow over the work pieces, which improves the uniformity of the process to give more homogenous finishes. The improved finishes are critical in industries were consistency is key for the manufacturing process and downstream applications such as bonding or coating.

To see how the wet blasting process could benefit your components, take a look at some of the industries we serve and their applications.

Alternatively you can contact us today to discuss how Vapormatt can fulfill your wet blasting needs.

With our core focus on process control, our wet blasting machines lead the way when it comes to repeatable and reliable processing.

We continue to add to our list of patents enabling customers to stay ahead of their competitors with market leading wet blasting technology.

Wet blasting is the use of an abrasive media and compressed air to achieve a desired finish on a chosen surface.