The preparation of cutting edges is a crucial element of the manufacturing process for cutting tool inserts, round shank tools, like mills, drills, taps and other tools like bandsaw blades.

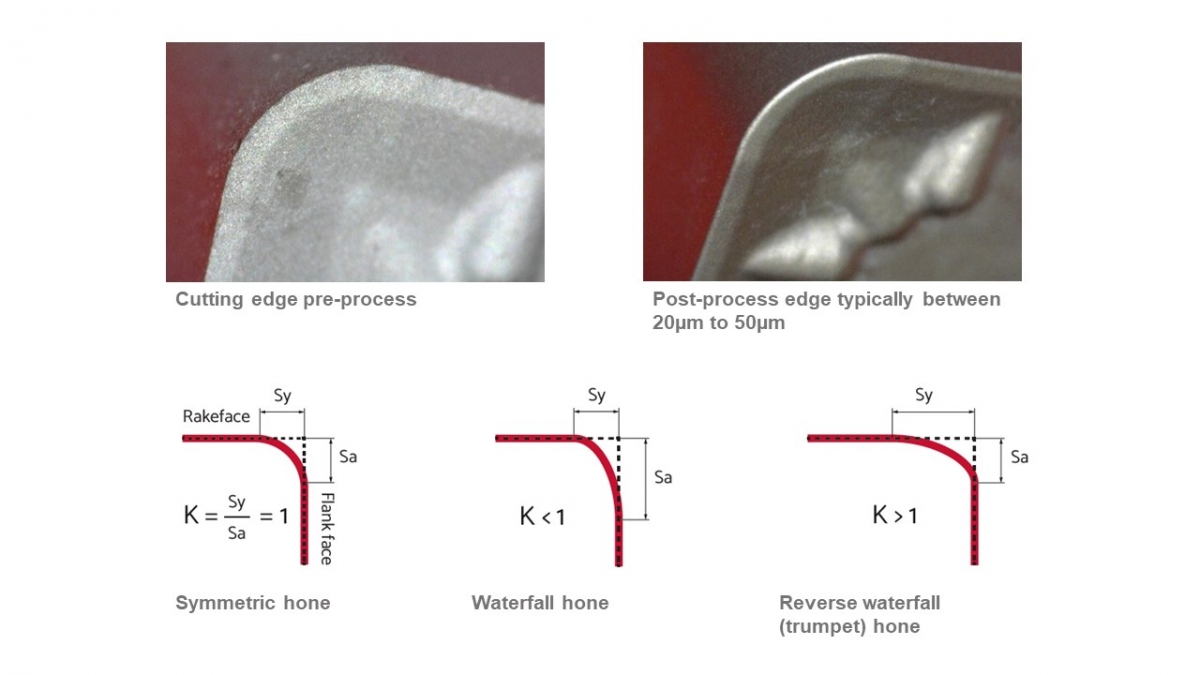

Like a newly sharpened pencil, a newly formed cutting edge is relatively fragile and significantly more prone to breaking - or ‘chipping’ in the case of cutting tools.

Continuing with the analogy, if you write with a pencil carefully it eventually blunts the tip slightly and the risk of snapping it is reduced. In the same way, a tool can be used slowly at first, in other words, ‘worn in’ to create a natural edge hone. The downside of this of course, is that production speed must be reduced whilst the tool is being ‘worn in.’

You can of course run the un-honed tool at full speed from new and it will, at first and for a short time, cut more quickly, but the chances of damage, especially ‘chipping’ are massively increased.

An additional factor that leads to the chipping of cutting edges is the build up of heat in un-honed tips. A shaper cutting edge makes for poor heat dissipation, and, with temperatures reaching upward of 1000 degrees celsius, can be another major cause of tool failure.

So, creating accurate edge hones on cutting edges significantly reduces wear rates, extending the life of the tool and in turn improving the quality perception of your tools and ultimately, your brand. For some tools the application of an edge hone can represent a two-fold increase in operating life.

And because the edge hone has already been applied, the need to ‘wear in’ the tool is eliminated. In fact, the tool can be run at full speed from new, so there is no reduction in production speed and subsequent productivity. Also, a honed cutting edge allows heat to spread evenly, reducing stresses and subsequent failure.

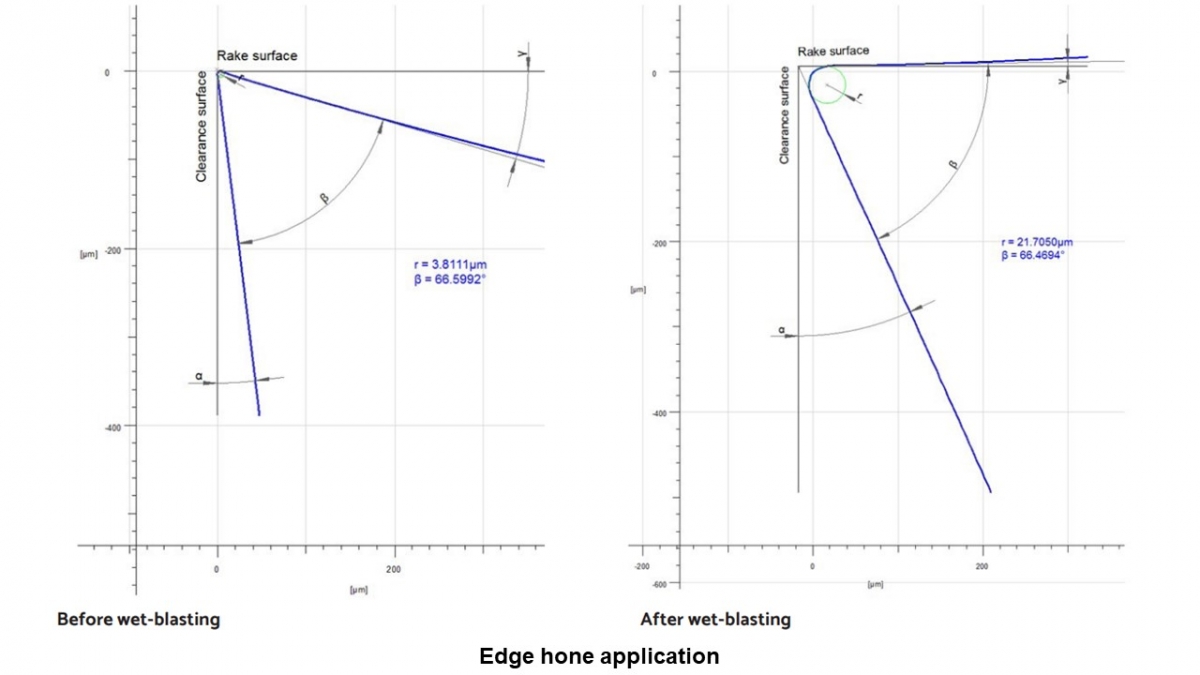

Our range of powerful wet blasting machines (or vapor blasting machines to use the alternative name) can deliver a precise and consistent edge hone to a specfic profile every time.

Profiles can range from trumpet to reverse trumpet hones (or waterfall hones) to suit the application of the cutting tool and typically edge hones applied tend to range from 30 to 40 microns but can range right up to a maxiumum of 70 microns.

We have a long history and lots of experience when it come to the edge preperation of cutting tools. Vapormatt have been delivering wet blasting machines (vapor blasting machines) for edge preparation since the 1970’s and we are now able to offer customers ultimate control over the size and shape of their cutting edges, all within very tight tolerances.

The success of the wet blasting (vapor blasting) process for edge preparation comes in its ability to offer very homogenous finishing across the cutting edges, something the wet blasting (vapor blasting) process is especially good at achieving.

The high degree of process control wet blasting (vapor blasting) provides allows for precisely the surface finish and edge hone required, much more in fact than comparable surface finishing processes like dry blasting or brushing.

Automation allows for the perfect surface finish to be applied consistently to the entire surface of the tool every time, with the added benefit of increased productivity.

As well as edge preparation, our wet blasting machines (vapor blasting machines) can combine processes, so as well as applying an edge hone to cutting edges, known areas of weakness can be peened for surface hardening – converting tensile stresses in the surface to compressive stresses, hence preventing failure. Tool surfaces are cleaned to a specific Ra too, giving a consistent aesthetic finish and a reactive surface too, that’s perfect for the application of surface treatments like oil, paint, and branding.

The video below illustrates how wet blasting can carry out multiple finishing processes on cutting tool inserts, including edge honing.

Our wet blasting machines (vapour blasting machines) can be configured to precisely your requirements and in the case of the automatic Profelis wet blasting machine, purposely designed for continuous products like bandsaw blades that operates in line with your existing production line.