Capable of withstanding extreme temperatures in excess of 375 degrees Celsius and pressures of well over 100,000 psi (by way of comparison a power washer runs at 2,500psi), aluminium extrusion dies are built from solid steel and are heat treated to cope with very extreme conditions.

As a result, they are expensive and represent a significant investment for extrusion businesses.

And with extrusion manufacturers trying to produce as much aluminium tonnage as possible every day, it is important dies perform as they should with minimal downtime.

Pulling a die, because of an issue with the extrusion, is particularly undesirable as it results in significant downtime and costs associated with inspection and correction.

The extreme operating conditions in the press can cause problems, like aluminium build up and subsequent wear or damage to the bearing face. This in turn, can lead to reduced capacity and delayed orders as a result of the bearing surface not being clean or smooth enough to keep the extrusion going.

The solution is to maintain the extrusion dies to a high standard with regular cleaning, inspections and corrections as required, an operation carried out by skilled, and often expensive, die correctors.

The first step in the cleaning, inspection and correction process is a caustic soda dip. This softens and removes heavy aluminium contamination, but smaller aluminium particles can remain along with discolouration from the heat and pressure of the extrusion process. The residual aluminium and discolouration makes die inspection extremely difficult.

To inspect dies properly, especially for smaller imperfections, dies have to be cleaned after the caustic soda dip stage.

Wet blasting (or vapor blasting to give it its other name) is more effective at cleaning extrusion dies than other surface finishing process. There are several reasons for this:

Wet blasted dies are left extremely clean making inspection and correction significantly quicker and more accurate. We would typically recommend an abrasive mixture of glass beads and aluminum oxide for speed and final finish. As a result, die correction is done to a much greater degree of accuracy, production runs are longer and there is less chance of failure and dies being pulled. The resulting return on investment (ROI) due to reduced inspection time and increased uptime is impressive.

To illustrate this, we have created a calculator that works out the potential savings and resulting ROI. One of our wet blasting experts will be more than happy to run through the calculation with you.

The effect of wet blasting aluminium extrusion dies (the image shows the effect on a spacer, it is identical for an extrusion die)

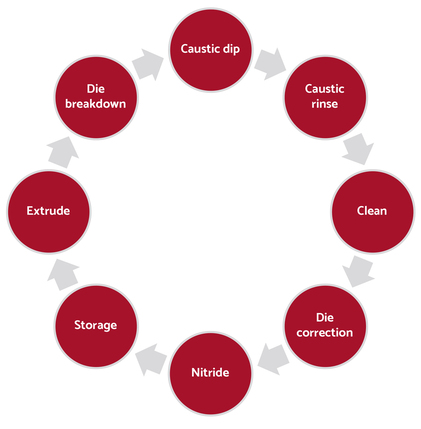

As per the die cycle diagram above, nitriding is a key aluminium extrusion plant operation. It is a process that diffuses nitrogen into the surface of the metal to create a hardened surface.

Surface activation aids the nitriding process, and the production of a reactive surface is another benefit of the wet blasting process. To prevent any corrosion from surface activation the wet blasting system is heated to aid drying and an corrosion inhibitor can be added to prevent oxidation.

Typical die cycle in an aluminium extrusion plant

Our decades of producing wet blasting machines (or vapor blasting machines to give them their other name) for use in extrusion die shops has led to the development of the automatic Cougar + wet blasting machine. Designed to cope with tough extrusion die cleaning operations it is extremely robust. It can also be configured to precisely match you extrusion die cleaning needs. Some of the configurable elements include:

Wet blasting cleans extrusion dies for inspection more efficiently than any other type of finishing process. It is a process that will not damage the edges of the profile and it is particularly good at cleaning complex profiles. Wet blasting also creates a surface that is perfect for nitriding.

Our automatic Cougar + wet blasting system can be configured to perfectly suit your extrusion die cleaning and nitriding operation.